Westminster Tool Inc. is a 26-year-old mold builder and molder that designs and produces injection and resin transfer molds for medical, automotive, packaging, aerospace/defense and industrial markets and also molds medical devices in high-temperature polymers plus machines metal components for aerospace/defense customers. The company holds SAE AS9100 and ISO 9001:2015 certifications, is ITAR registered and is NIST SP 800-171 compliant. Photo Credit: Westminster Tool Inc.

No stranger to MoldMaking Technology (MMT) readers, Westminster Tool Inc. has twice been named the magazine’s Leadtime Leader (in 2014 and 2021) and three employees were named to MMT’s 30 Under 30 list in 2021. Company founder and president Ray Coombs also received the Mold Builder of the Year award from the American Mold Builders Assn. (AMBA) in 2021.

The company specializes in high-complexity, tight-tolerance molds for the medical industry that are typically sized for presses with clamp tonnage between 10 and 350 tons, although the company’s sweet spot is between 100 and 250 tons. Photo Credit: Westminster Tool Inc.

With a team of 35 people and 26,000 square feet/2,416 square meters of floor space, the company produces 20-25 small-to-medium size injection and resin transfer molds per year with a specialty in high-complexity, tight-tolerance molds for the medical industry. Production tools are typically sized for presses with clamp tonnage between 10 and 350 tons/9.1 and 318 metric tons. Additionally, the company injection molds and provides custom CNC machining of metal parts.

Initial Implementation Failure

Because Westminster Tool has a strong cultural focus on continuous improvement and accountability, management wanted to better understand how effectively its CNC and EDM machines were being used. In 2017, to save money, the company installed a machine monitoring system and the system’s software and hardware on nine CNC and EDM machines itself. Two years later, when Colby Coombs joined the company as CFO, he learned the team was disputing machine uptime numbers the system was reporting.

“With my background in finance, I know how critical accurate data on uptime and throughput are to planning, scheduling and understanding the current health of a company,” recalls Colby. “As a moldmaker, your two greatest investments are people and equipment. Everyone tracks labor hours to see how the team is allocating its time. However, suppose you don’t have accurate and useful machine data to go along with that. In that case, it’s almost impossible to understand true shop capacity, make informed decisions about investments in automation and new equipment, and find ways to improve efficiency and debottleneck problem areas.”

Now, with team buy-in, utilization data are scrutinized every Monday at production meetings and team members share best practices to increase throughput.

When looking to better understand what went wrong with the 2017 installation, Westminster Tool management identified two issues. The first was that when they had connected the hardware portion of the monitoring system, the company’s technicians had hooked the device up to the wrong set of wires on several EDM machines, which meant the system thought EDM machines were running when they were just turned on. That explained why the team didn’t trust the data they were seeing. The second issue was that management hadn’t explained the benefits of the technology and sought buy-in from team members, who felt they were being policed rather than given a tool to increase efficiency and throughput and make the company more competitive.

“We realized we had an implementation failure the first time around, which is why we weren’t getting accurate data and why our team wasn’t onboard with using the system, so we decided to make a hard reset and start again,” adds Colby.

Side-by-Side Comparison

Management at Westminster Tool decided to compare the performance and accuracy of three different machine monitoring systems. This time, they involved shop leaders to help identify which systems would best meet company needs and select the machines on which comparisons would be run: one sinker and one wire EDM that each gave the team trouble, and a soft mill that was problem-free and should be easy to track. The implementation team also defined three criteria for judging competitors: customer service, data accuracy and system flexibility in measuring key performance indicators (KPIs).

Because each candidate system collected data slightly differently — one measured amperage draw, one evaluated controller executables and one monitored both — the decision was made to install all three systems on the three target machines and run them side by side to evaluate accuracy.

“One competitor quickly self-selected itself out of the competition through poor service,” chuckles Colby, who explains that the two remaining systems ran side by side for a solid month as benchmarking continued. The operator running each target machine manually logged when the equipment was running and when it was not, and the implementation team pulled weekly reports from each monitoring system and compared them to each other and against technicians’ logs, then compared overall accuracy at the end of the month of benchmarking.

“When we looked at the data, it was clear that the InFocus AutoTrack platform from R.E.R. Software Inc. was unmatched in its accuracy and flexibility,” Colby adds. “They also proved over and over to offer the best customer service.”

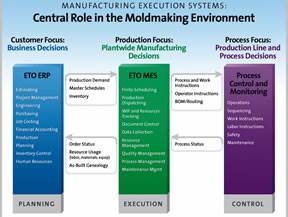

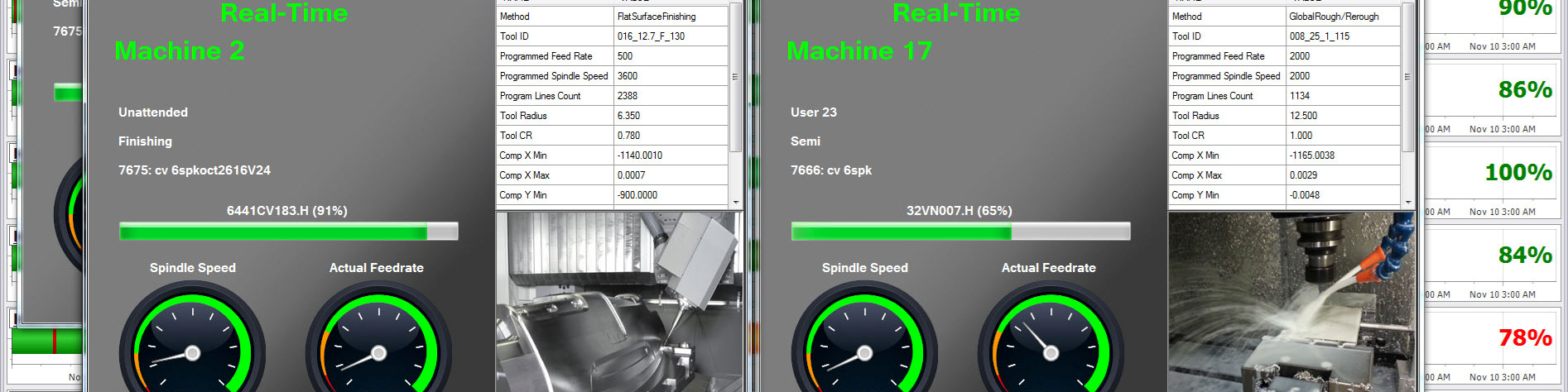

R.E.R. platforms use a business intelligence (BI) dashboard and supervisory control and data acquisition (SCADA) collection and reporting framework preconfigured specifically for mold and die shops. Photo Credit: R.E.R. Software Inc.

Designed for Toolmakers

R.E.R. was cofounded in 2016 by the Bassous brothers, Roger, president, Edward, optimization consultant and Richard, CTO. Edward had spent 16+ years working for a large local moldmaker as a 3D development leader. Roger and Richard were software engineers who’d spent the early part of their careers working for software solutions provider Compuware Corp. In 2008, they cofounded RerWare LLC, which provided mobile and computer backup services. Putting the brothers’ backgrounds in toolmaking and software development to work, R.E.R. Software specialized in developing manufacturing technology to increase efficiency and provide operational oversight. Customers initially hailed from the North American tool and die industry, but now molders and production CNC machining companies also use the software.

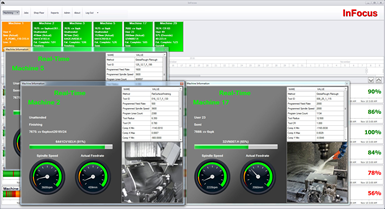

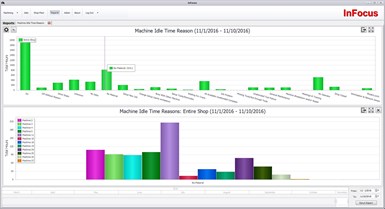

With the InFocus AutoTrack system, it’s easy to determine which machines are not running and why, and compare shop data over different periods of time. Photo Credit: R.E.R. Software Inc.

R.E.R.’s initial product was InFocus AutoTrack, a machine monitoring platform providing dynamic and historical reporting on machine uptime and labor usage. Next, InFocus AutoPlan, a computer-aided scheduling tool, was commercialized. Last year, the InFocus SmartAlert dynamic notification system was added.

“Each package can run independently, but together they provide a very robust offering for manufacturers,” notes Edward. “For most customers, the software is a turnkey, out-of-box solution, although we also offer customization for those needing it. Customers can try the software free before purchasing, and each system is sold on an SAS [software-as-service/annual license] basis, making it easy to evaluate, cost-effective to implement and flexible to add machines as customers gain experience and expand operations.”

“Our strong relationships with controller manufacturers enable our software to pull data from individual machine controllers directly into our system for unparalleled accuracy. From the moment the system is hooked up, moldmakers start receiving actionable information.”

“We use smart technology algorithms to train each platform to make it smarter over time,” adds Roger. “Our platforms use a BI [business intelligence] dashboard and SCADA [supervisory control and data acquisition] collection and reporting framework preconfigured specifically to tool and die shops, but all screens are configurable and it’s easy to modify reports as needed. Our strong relationships with controller manufacturers enable our software to pull data from individual machine controllers directly into our system for unparalleled accuracy. From the moment the system is hooked up, moldmakers start receiving actionable information.”

Getting a quick visual snapshot of plant productivity is easy. For large companies with multiple locations, comparisons can be made between machines in a single facility and multiple machines in multiple facilities. Photo Credit: R.E.R. Software Inc.

Working with a customer’s information technology (IT) department, the software portion of the InFocus AutoTrack program is installed on the central server. Most newer (post-2005) CNC machines needn’t be shut down and older machines are typically down for less than two hours during installation. Operating data are pulled directly from controller software if a machine uses such a system, or from direct measurement of current draw measured via an Internet of Things (IoT) device connected to machine wiring on equipment like sinker and wire EDMs.

Better than Before

Westminster Tool deployed the InFocus AutoTrack platform in Q4 2021 and installed it on 15 machines: 10 CNCs plus two sinker and three wire EDMs. “When the R.E.R. technician arrived to install the system, he allowed a couple of our team members to shadow him, so if we bought another EDM, we’d know how to hook it up correctly,” notes Colby. “Also, their software was easy to customize based on the KPIs we wanted to measure and how we wanted reports to look. We installed monitors on all the machines so operators can see in real time what’s happening and how productivity on that machine compares with its performance last week or last month as well as against other similar machines in our shop.”

Not long after data started coming in, the Westminster Tool team realized they wanted the software to report the average start time for equipment, which would indicate how long each machine spent warming up. “We worked with Roger’s team and not only did they help us start tracking start time, but they also added that metric for other customers using the system,” continues Colby. “With data in hand, we realized we didn’t need to warm up machines as long as we’d been doing. Also, we started prepping them the night before so they could start producing product earlier the next day, which increased productivity and throughput.”

Another benefit of the system was that it increased the company’s scheduling flexibility and enabled the team to increase output and revenue. “The system clearly showed us where we had open capacity, so on machines with automation capabilities, we took on more work aligned with our specialty and complimented our excess capacity by machining components rather than letting those machines sit idle,” adds Colby. “Also, because the system gives operators the flexibility to improve themselves and the workflow, when we see that Project A can’t start because material or CAD files didn’t come in, but Project B is ready to go, we start Project B so throughput stays high.” Now, with team buy-in, utilization data are scrutinized every Monday at production meetings and team members share best practices to increase throughput.

With a culture focused on continuous improvement and accountability, Westminster Tool uses data from its InFocus AutoTrack platform to increase machine utilization, improve on-time deliveries, and increase shop capacity and revenue. Team buy-in was critical to using the tool to make the company more competitive. Photo Credit: Westminster Tool Inc.

With roughly 24 months of data under their belts, what kind of results has Westminster Tool seen? “First, our average start time improved by 8.17% across all machines, which translates to roughly an extra hour of work per day across all 15 machines we track, or almost 75 hours of additional capacity per week,” notes Colby. “In our first 12 months, we increased utilization by 14.64% and improved our on-time KPI by 16%.” He notes that the data are so accurate and trustworthy that it now guides Westminster Tool’s CAPEX decisions. “We delayed buying an extra sinker EDM because the system showed us how to utilize the two machines we had more efficiently,” he adds. “Tracking machine utilization has improved our culture and helped us move more parts through our shop and deliver them to customers. Also, we achieved these improvements without adding machines and with slightly fewer people.”

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

VIDEO: To Solve the Skilled Labor Problem, Change the Culture

MoldMaking Technology Editorial Director Christina Fuges teamed up with Modern Machine Shop Editor-in-Chief Pete Zelinski onsite at Westminster Tool in Plainfield, Connecticut to experience live the company’s unique culture, and then digitally capture the spirit of the environment to share with the rest of the manufacturing community.

Read MoreSnapshot of Why Westminster Tool is MMT's 2021 Leadtime Leader Winner

Here is a quick look at some of the reasons this small advanced manufacturer took the title this year.

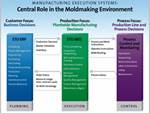

Read MoreManufacturing Execution Systems for Mold Manufacturers

A look at a system for mold manufacturers that can be used to measure and control critical production activities.

Read More

.jpg;width=70;height=70;mode=crop)