Changes to Electrode Material And EDM Program Yield Increased Throughput

A look at the positive effects of a change of electrode material.

Rexam Mold Manufacturing (RMM; Buffalo Grove, IL) is one of the world’s leading producers of closures for a wide range of uses to include beverages, foods and containers for industries from household to healthcare. Their distinction comes from a level of excellence that all Rexam associates strive to maintain and allows the organization to produce products of the highest quality standards. Jack Fiorito, Special Tooling Manager is one of these individuals. Recently, Fiorito was involved in a project for several cores to be produced out of a high strength alloy popular in the industry for its thermal properties.

Problem

When a high thermal conductive material is EDMed, the energy of the EDM spark is easily dissipated throughout the workpiece. EDMing this material in the same manner as more common metals yields reduced performances and increases the electrode wear.

Fiorito experienced this when EDMing the cores with POCO EDM-3. Due to the negative polarity on the EDM required to burn this workmetal, he was met with the dilemma of needing additional electrodes in order to get the job completed. For the number of cores on this job, Fiorito calculated that 48 electrodes would be sufficient; however, after making the first set of burns he realized that this job would ultimately require 73 electrodes.

At this time, Fiorito contacted Dave Pedersen, an EDM Applications Sales Specialist with Poco Graphite. Pedersen suggested a change in the electrode material from EDM-3 to EDM-C3, a copper-impregnated electrode material more suited to EDMing thermally conductive materials. In addition to recommending a different electrode material, Dave also suggested slight changes to the EDM program.

Result

There is a common practice of using a more economical electrode when EDMing materials high thermal conductive material; however, Fiorito knew that it was more important to focus on the overall manufacturing cost as opposed to only the individual electrode cost.

While working together, Fiorito and Pedersen were able to reduce the amount of electrodes required as well as the EDM time to complete the job. The number of electrodes required dropped back down from 73 to 38. With EDM-3, the burn time was 3.5 hours per core while the EDM-C3 burned each core in 2.0 hours.

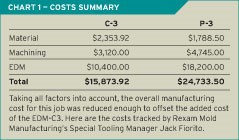

Taking all factors into account, the overall manufacturing cost for this job was reduced enough to offset the added cost of the EDM-C3. Interestingly enough, Fiorito tracked the costs and provided the summary in the Chart.

While the EDM-C3 material costs twice as much as EDM-3 per electrode, the overall manufacturing costs on this job were reduced by more than $8,850.00. In addition to this, with the amount of hours saved machining fewer electrodes and the reduced EDM time, Fiorito and Pedersen calculated that an additional 140 hours of increased throughput can be realized.

Note:

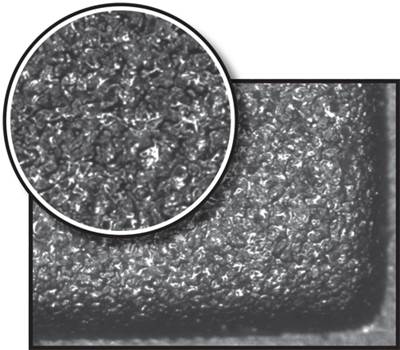

The new Business Unit Manager at Rexam Mold Manufacturing, Len Graham, is guiding the EDM

department to full palletization of electrodes and mold components—both referenced to a palletized

precision gage ball followed by robotic setting and unloading of the same. These pictures were taken prior to those very recent high level management changes and do not reflect the new processes currently being implemented.

For More Information:

Rexam Mold Manufacturing

rexam.com/mold

Related Content

How to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreHybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreRead Next

Electrode Material Effect on CNC EDM, Part 1

When all the factors of the EDM process are taken into consideration, savings on the electrode material cost can result in a much larger overall cost.

Read MoreElectrode Material effect On CNC EDM, Part 2

A discussion of the reasons why the use of more, economical electrode material is not always the most cost-efficient means of CNC EDM

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More