An Industry 4.0 Proving Ground

By making use of data collected directly from its machines, this mold manufacturer is riding the wave to the next industrial revolution.

Steve Jarzynski is on a mission to bring Rochester Hills, Michigan-based Hi-Tech Mold and Engineering fully into the age of digital manufacturing, and the successful launch of the company’s newly established technology center is a principal guiding force. Jarzynski is a member of corporate program management and engineering at Baxter Enterprises in Winchester, Tennessee, an injection molding operation that was part of the large injection mold builder’s expansion into the southeast in 1997. He has been leading both companies in their pursuit of offering customers more efficient, digitally driven and connected manufacturing services by embracing Industry 4.0 ideologies.

“Industry 4.0 is a living, breathing thing, and it can mean different things to different people,” Jarzynski says. “For Hi-Tech Mold, it means consistently collecting and measuring ‘big data’ from our machines using sensors and monitors, and then applying those metrics so that we can adapt, in real time, to what’s happening on the production floor and make more effective decisions. It’s everyone in the supply chain working together concurrently, through a high level of connectivity in the cloud or with dedicated fiber, to optimize production. Our tech center is a model for how we want all of our plants to work. In fact, the entire Rochester Hills campus is a great place to study Industry 4.0, because it’s a proving ground.”

Founded by Siegfried “Siggy” Schulte in 1982 under the name Amtech Mold and Engineering Inc. in Fraser, Michigan, a majority of Hi-Tech Mold’s business has been dedicated to building molds for the automotive industry. Robert Schulte, president and CEO of the Hi-Tech Mold and Baxter group of companies, continues the tradition today. In 1987, the company built the first building at its current location, relocated there, and changed its name to Hi-Tech Mold and Engineering to more accurately represent its level of capabilities and its newfound mission statement: “Superior quality through higher technology.” Nearly 30 years later, four buildings, including the tech center, make up the Michigan campus and a new, more powerful mission statement is said to evoke the Industry 4.0 mindset: “We achieve excellence with high-performing teams producing high-quality results utilizing innovative thinking and advanced technology.” Based on its success on the Michigan campus, Hi-Tech Mold recently broke ground in Westminster, South Carolina, on an 88,000-square-foot plant that will house Hi-Tech Mold Carolina and Baxter Manufacturing. It also will be equipped for Industry 4.0.

Sensors and Monitors

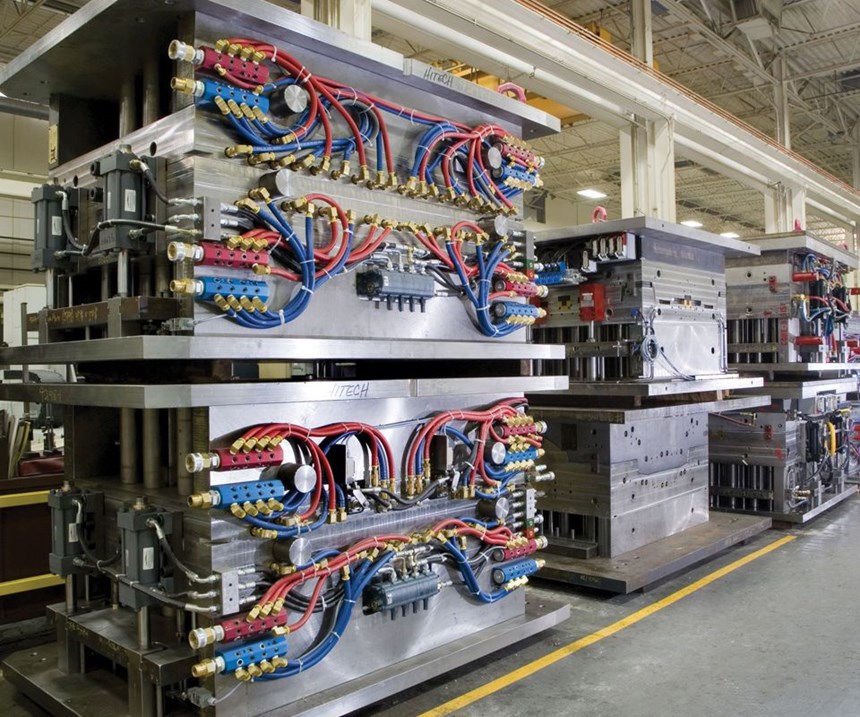

Originally, the 14,000-square-foot technology center housed standard injection molding equipment, which Jarzynski says limited the company’s ability to not only advance its molding processes and implement the latest in automation equipment, but to support the technically advanced molds it builds. These include large injection-compression, thin-wall and hybrid lightweighting molds ranging in size from 50 to 4,000 tons for automotive manufacturers such as GM and BMW, and for Tier-One suppliers like Magna International.

To overcome the limitations and allow for mold tryouts, the company decided to renovate and collaborated with injection molding machine manufacturer Engel to equip it with “smart” molding machines designed specifically with Industry 4.0 functionality, including the ability to network and be integrated with other production systems; provide access to valuable process and production data; and be increasingly efficient and flexible, yet simpler to manage. These machines enable users to set process quality parameters specific to each injection molding program and, through the use of sensors, monitor and control them to optimize productivity, Jarzynski says.

“Ultimately, we built more than just a tryout facility; we are also able to validate a process and formulate a template for how we want our other facilities to work,” he says. Hi-Tech Mold’s collaboration with Engel Machinery provides a cutting-edge production showroom and development facility for further testing and advancing “smart factory” initiatives.

The center is now equipped with three Engel machines: a 3,500-ton, a wide-platen 1,000-ton and a 340-ton tie-bar-less unit, each integrated with an Engel three-axis linear robot. A fourth 660-ton machine will be installed in the first quarter of 2017, and a fifth machine is planned for some time next year, Jarzynski says.

Hi-Tech Mold uses these machines primarily to try out the molds it builds, but Jarzynski says that other smart features help further the company’s progression to more data-driven manufacturing. For example, Engel’s eConnect app enables customers to check machine and production status in real time using smartphones or tablets, and then request spare parts or other service.

Cables and Clouds

The company currently manages its own servers to connect the Michigan campus with the Tennessee campus, but Jarzynski says that will change with the completion of the South Carolina facility at the end of this year. At that time, the new Hi-Tech Mold location will be connected through the cloud, using the services of a third-party internet infrastructure provider, also known as a server farm. This will better meet the growing company’s internet capability needs, including relating to speed and security, he says.

The trend toward cloud computing is a key characteristic of Industry 4.0, and High-Tech Mold is implementing it in other ways throughout its operations. All of the company’s internal work schedules are maintained digitally, and employees work from solid models rather than blueprints and drawings. While some paper documents, such as trucking manifests and the like, are still required, the company is essentially paperless, and Jarzynski says this gives it the ability to maintain flexibility and adaptability in its approach to product development, manufacturing and lifecycle support.

Like many moldmaking companies, Hi-Tech Mold used to use a home-grown system to manage operations, but Jarzynski says its capabilities became more and more limited as the company grew. In August 2015, it invested in an enterprise resource planning (ERP) system called Microsoft Dynamics AX that connects the entire organization, including every plant, department and even conference room through the cloud. This system features what Microsoft terms “pervasive interoperability,” in which familiar Microsoft business applications such as Word and Excel and the underlying technology platform work seamlessly. It was purposefully designed to be manufacturing-focused and enables efficient scheduling of resources to jobs and operations, using IT infrastructure technology and business and productivity applications like Kanban scheduling boards, key performance indicators and other report functions that the company can tailor to its needs.

This ERP system and the data-driven measures implemented in the revamped technology center are moving Hi-Tech Mold closer to Jarzynski’s vision of fully digital manufacturing. “Industry 4.0 is not just having the equipment and molds, it’s also the mindset and the application of it,” he says. “Today, on the molding side, we’re monitoring cycle times, machine activity, scrap rates, PMs and repair downtime. With all of the data mining we’re doing at our tech center and in other departments, we can measure our overall equipment effectiveness to ensure we are optimizing efficiencies, performance and quality throughout our manufacturing operations.”

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More