A Final Line Of Defense to Making A Quality Program And Product

“We use and rely on VERICUT to verify quality, datum shifts, and cutter path manipulation.”

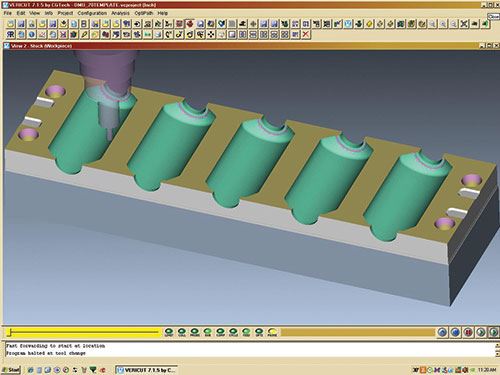

CNC Machining Software Verifies Cutter Path Manipulation, Quality

M.C. Molds, Inc. (Williamstown, MI) is a blow mold manufacturer for the commercial bottle and medical industries while also specializing in the design and build of machine-specific trim tooling from concept through final product. The company has been using VERICUT CNC machining software from CGTech (Irvine, CA) for the past 18 years to ensure its customers receive the highest quality product.

It was M.C. Molds President Bob Palazzolo who decided upon VERICUT after looking at several packages. According to CNC Programming Leader Bob Tuite, the department uses SURFCAM, Power Mill and WorkNC along with VERICUT to ensure quality of the machined product. “When I first started here, I could not understand the need for using VERICUT,” Tuite recalls. “I had been operating machines and programming for more than 35 years. I was used to sending single programs or looping, merging of multiple programs and tool pods to the operators. It took only a couple weeks for me to realize the

importance of this VERICUT verification software.”

According to CGTech Marketing Communications Manager Bryan Jacobs, “VERICUT interactively simulates the material removal process of an NC program. This information can then be used to correct inefficient motion or programming errors.

VERICUT’s unique algorithm provides fast, accurate results and performance does not degrade with increased cuts, so it can process programs with millions of cuts and virtually any type of material removal technique.

“The program supports G-codes and provides multi-axis support for milling, drilling, turning, grinding and EDM machines; simultaneous mill/turn on different spindles and workpieces; and automatic workpiece transfer to pick-off or sub-spindles,” he adds.

The CNC department at M.C. Molds programs a single cavity at zero and then datum shift to make multiple cavity molds, Tuite states. “We not only program 2D and 3D, but also program 3+2 and full five-axis programs,” he elaborates. “For most of our jobs we do not run rough, semi and finish toolpaths; we only rough and finish. By doing so, we eliminate one more process—cutting our machining time down by at least 33 percent.”

But skipping the semi-finishing pass means the programmers must be very aware of how much material they are leaving following the roughing process. “If, after running the program through VERICUT, there wasn’t any red appearing onscreen to show a problem, they believed it must be good to run. However, it didn’t mean it was programmed right.”

Although VERICUT was simulating exactly what was programmed, Tuite believes that philosophy began to reflect negatively on VERICUT on the shop floor. “What looked good in VERICUT didn’t always mean what was happening in the shop—when it comes to things like cutter pull etc.—was right,” he says. “By not watching some of the toolpath in VERICUT, the programmer really doesn’t see if he has possibly left too much stock in the corners to finish.”

“We have so many jobs come through here, as well as many changes to existing jobs,” Tuite adds. “We use it to verify that we are putting out to the floor exactly what is being called out on the prints, and work orders. For example, if a customer wants to increase the volume of parts the mold produces, we will pull up the original file and run the new changes over it to verify the programs are cutting when and where it was intended.”

VERICUT is relatively easy to learn—and run, according to Tuite. He was able to train himself and employees in a few weeks’ time. “It’s very hands-on,” he emphasizes. “Honestly, to be able to go home at night and not have to worry about the program failing or a major crash or any type of problem is a great relief to us all,” he emphasizes.

Simulation Advantages

Tuite notes that although the initial programming time is about the same, the welding and scrap has decreased 75 percent— plus his operators have more confidence that what is coming to them is exactly what was intended. “We watch to see if we possibly need to optimize our roughing and reroughing strategies, as well as tool and toolholder collision checking,” he explains. “Although most CAM software programs out there have cutter lengths holder checks, VERICUT also offers a real-time optimizing of tool and holder lengths,” he comments. “The software automatically adjusts tool lengths to holder to verify the proper tool length is sent to the operator. VERICUT is our final line of defense to making a quality program and product. It is icing on the cake as far as processing toolpaths for the build of molds.”

“We use and rely on VERICUT to verify datum shifts, cutter path manipulation, and most of all quality,” adds Palazzolo. “I am happy to attest that VERICUT, the software and people have been very helpful with regards to our—and our customers’—success.”

For more information:

M.C. Molds, Inc. / (517) 655-5481

bobt@mcmolds.com / mcmolds.com

Related Content

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreHow to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreSpeed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreRead Next

NC Simulation Software Verifies Machining Paths—A Critical Step in the Build Process

“VERICUT facilitates our goal of eliminating the need for rework (welding, for example)—improving quality and repeatability, and saving MGS and our customers time and money.”

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More