Photo credit clockwise, from top left: Wisconsin Engraving, Fisa North America, Custom Etch and St. Paul Engraving

The Plastics Technology Expo (PTXPO), taking place this year March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, brings partners across the supply chain together, bringing energy and excitement to the show floor.

To provide a little more insight into who our product, equipment or service suppliers are before you arrive at PTXPO, the MMT team put together this special show section* that provides a snapshot of each exhibitor most relevant to moldmaking.

For all things mold maintenance, repair and surface treatment, check out the profiles below. Each of the profiles outlines companies exhibiting these services and solutions at PTXPO 2023 in or around the MoldMaking Pavilion. Booths not located in the Moldmaking Pavilion are denoted with two asterisks and information on their location.

Use promo code MMT23 and register today for your FREE exhibit hall pass and we’ll see YOU in Chicago!

*This exhibitor list is subject to change. Current as of 2/23/23

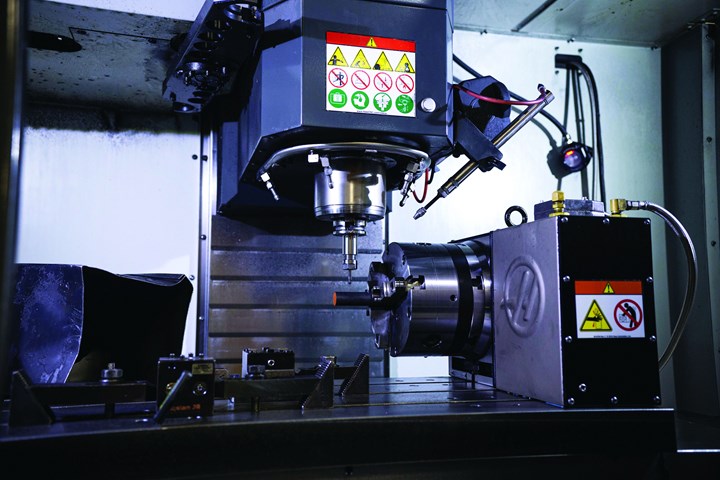

Get to Know Alliance Specialties and Laser Sales

Moldmaking is important to Alliance because it is the foundation for everything it does — developing deep-rooted relationships and making a difference. Alliance’s team are moldmakers who don’t build molds, but rather partner with moldmakers to be the solution that they need, for the things that they don't have the time or the desire to do.

Photo Credit: Alliance Specialties and Laser

Alliance is always learning how it can best serve the industry, and it has done this through clearly understanding what it is as a company. Over the years, Alliance has developed the process and ability to be a one-stop destination/hub to handle every mold-related issue when it comes to finishing and repair — polishing, mold repair and maintenance, laser welding and engraving, as well as hot runner repair. This dedication to serving the industry has led Alliance to create its U.S.-made fiber laser welding and engraving systems built specifically for mold builders and toolrooms.

At Booth 1426, Alliance and its team will be putting their full selves on display with a focus on who the company is and how they make a difference. Stop by to take part in live Manufacturing Alliance Podcast interviews and games throughout the week or learn more about Alliance’s newest laser welding and engraving systems. Solutions specialists will be on hand to discuss any challenges or stresses you are facing.

Get to Know Custom Etch Inc.

Custom Etch specializes in innovative textures for the moldmaking industry. Molds that require the company’s services are normally in their final states, and as a result, all necessary measures are taken into consideration, with customer specifications and expectations fully executed. Custom Etch always strives to be the best in the industry regarding quality, lead time and cost.

Photo Credit: Custom Etch

Custom Etch’s texturing capabilities can be achieved with the traditional chemical etching process or five-axis laser technology. The company is capable of creating any texture needs, either by traditional textures or even digital watermark textures. Support and collaboration with moldmaking leaders keep the company on the newest/latest technology advancements.

Learn more at Booth 809 about the company’s texturing offerings, including Custom Etch’s Innovated Digital Watermarks, which can provide brand protection, recyclability and traceability. All market segments will be showcased. Samples from chemical etching and laser technology will be on display for viewing. Custom Etch will also have many Digital Watermark Textures samples to show and give away. Stop by and say hi to Don Melonio, owner and Chad Hase, director, for details.

**Find Custom Etch in the Injection & Blow Molding Pavilion

Get to Know Precision Laser Technology

In the last 25 years, Precision Laser Technology (PLT) has exposed manufacturers to the advantages of lasers within their mold building operations. Initially, lasers were a solution for cleaner and faster milling /EDM cavity IDs and logos. Over time, however, lasers have supplanted TIG for welding repairs, acid for texturing and scribing tools for mold specs and traceability. Today, every mold shop utilizes lasers in some capacity, and they continue to be a vital component to U.S. manufacturing.

Photo Credit: Precision Laser Technology

In Booth 1419, PLT will be educating and connecting with customers about its laser services offerings. Its booth theme, “Supporting Global Mold Builders with Proven Laser Solutions,” emphasizes PLT’s ability to meet the service needs of mold building consistently.

Get to Know Slide Products

Visit Booth 1627 to meet the Slide Products’ team of experts with more than 100 years of field experience and insight into the needs of mold builders and molders when it comes to mold care. The team will be sharing best practice documents and product recommendations with free samples. You can also schedule a Top Tier Service on-site visit so an expert can see your problems firsthand and offer product recommendations and process improvements. Slide’s sales team is made up of five industry veterans with more than 100 years of experience between them, and that’s who you’ll see working in the booth. Slide Products will be displaying its mold cleaners, rust preventives, mold releases and MRO products, and will have free samples of many of the products available at the booth for customers to take with them.

Slide’s complete line of mold care products — mold cleaners, rust preventives, ejector pin grease and MRO formulations — have helped to improve the performance and profitability of moldmakers. For 70 years, Slide has listened to its moldmaking customers and expanded its product line to include solutions designed to address their specific needs, and moldmakers themselves have relied on Slide Products for fast cleaning, rust protection and the reliably smooth processing that comes with having the right formulation for the job. Without moldmaking, Slide says it wouldn't have much of a business.

Slide Products is among the first in the industry to eliminate the usage of chlorinated solvents — substances such as trichloroethylene (TCE) that are known to cause cancer — in all of its formulations, long before stricter regulations were implemented.

Photo Credit: Slide Products

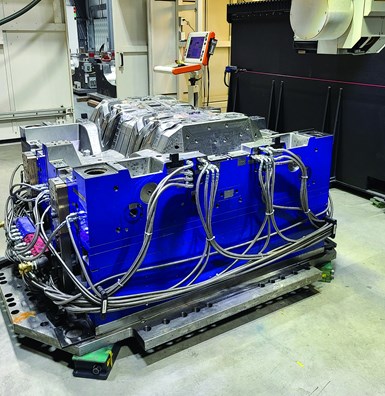

Get to Know Wisconsin Engraving

Visit Booth 1324, a place where mold builders and their customers can come to help alleviate their bottlenecks. In the booth, Wisconsin Engraving is featuring its most knowledgeable employees, people who represent 25 plus years of engraving and texturing experience along with 10 plus years of five-axis laser texturing/ablation experience, to answer questions and highlight its new and proven technologies.

Moldmakers are Wisconsin Engraving’s life blood. Constant technological innovations have been sought after to support the company’s mold building customers. This includes innovations, enhancements and investment in new engraving techniques, along with five-axis laser texturing/ablation machines.

Photo Credit: Wisconsin Engraving

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More