Maintenance & Repair

The MoldMaking Conference: All About Next-Level Mold Maintenance

Here we spotlight the Maintenance block of sessions of the MoldMaking Conference – for the next-level mold manufacturer – November 8 & 9 in Charlotte, North Carolina.

WatchHot Runner Systems, Controllers, Auxiliary Injection Unit Exhibitions

Mold-Masters exhibits a wide variety of new and enhanced systems and technologies at K Show like the TempMaster manifold plastic leak detection, the PET-Series two-stage hot runner system and Fusion Series G3.

Read MoreMold Monitoring System Provides Real-Time Mold Performance Monitoring

Arburg showcases a range of machines highlighting digitalized manufacturing including the Hack Moldlife Sense system, used to detect and notify operators about errors and irregularities in the mold.

WatchMMT Ask the Expert: Hot Runner Benefits and the Fundamentals of Maintenance and Refurbishment

In this next portion of our “Ask the Expert” series, Husky’s Derrick Hennebicque answers some FAQs about the advantages of hot runner systems and refurbishment strategies. This episode is brought to you by Husky, Melt to Mold Precision.

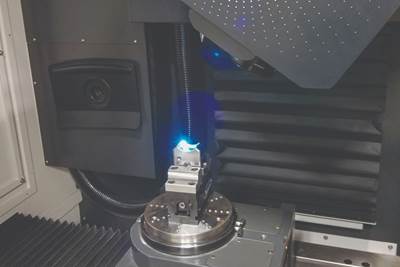

WatchLaser Welding Workstation Adds to Changing Landscape of Mold Repair

LaserStar Technologies’ FiberStar 8801, to be showcased at IMTS 2022, combines power and precision with an adjustable workspace for repairing molds.

Read MoreHigh-Performance Grease Targets Industrial Applications

Nanoplas’ NSF H1-accredited Min-Lube offers exceptional water and water resistance, antimicrobial protection and extends the lifetime of machinery. It’s applicable for use with mold components.

Read More2022 Sourcing & Technology Guide: Mold Maintenance, Repair and Surface Treatment

A proactive maintenance plan to properly treat a mold to keep it running will decrease repair costs. Proper treatment of the mold’s surface is key to quality, corrosion-resistance, wear and tool life.

Read MoreCeramic Deburring, Deflashing Tools Take Into Consideration Difficult Materials, Operator Safety

Boride Engineered Abrasives introduces its new mold polishing equipment, the Work Finisher Tool, which is lightweight, long lasting, won’t rust and is safer and easier to use.

Read MoreMiscellaneous Technology Roundup

MoldMaking Technology compiles a list of digital-only products and services from the past month, from machining safety and injection molding training courses, to CNC programming software and cutting tools.

Read MoreTechnology Roundup: Maintenance, Repair, Surface Treatment Tools

Selecting the right maintenance, repair or surface treatment tool is critical to making an operation run smoothly, and sometimes it can determine if it runs at all.

Read More