Maintenance & Repair

VIDEO: Hot Runner Maintenance Tips

Scott Clark, Hot Runner Business Manager for Husky Technologies, breaks down maintenance practices for hot runner systems.

WatchMold Care, 3D Scanner Best Practices, the State of Maintenance & More Most-Viewed April Content

April held a little bit of everything for MoldMaking Technology. From mold care and maintenance to 3D scanner and printing best practices, take a look at what might have missed your radar.

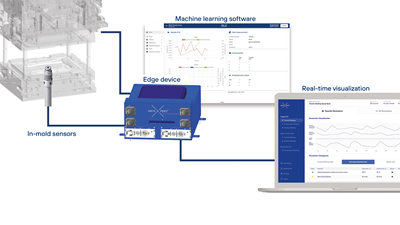

Read MoreIn-Mold Sensor Technology Assists With Sustainability Goals

SensXpert Digital Mold from Netzsch Process Intelligence is intended to help the plastics industry reach governmental and environmental sustainability goals.

Read MoreMMT Chats: SPE MTD 2023 Mold Repair Person of the Year

MoldMaking Technology Editorial Director Christina Fuges sits down with the newly named SPE Mold Technologies Division 2023 Mold Repair Person of the Year to learn about his passion for mold repair. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchMold Lifting Rings Offer Efficient Mold and Die Management

PCS Company's Codipro Mold Lifting Rings are said to provide more efficient material handling and moving of molds and dies in any shop or molding facility.

Read MoreHoist Rings Offer Safe, High-Clearance Lifting of Molds

Jergens Inc. adds a productive and secure solution to die flipping and lifting large, heavy molds that meets strict quality standards and maintains the structural integrity of the objects being lifted.

Read MoreVIDEO: Maintaining a Customer-Centric Culture

Progressive Components President Glenn Starkey talks about the importance of the customer and culture when developing technology solutions for the moldmaking industry.

WatchVIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.

WatchCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreThe State of Maintenance: Where Are You?

New products, equipment and software are beneficial to mold maintenance, but they do not change the fundamental way a repair technician performs the job if the culture remains reactive. Is your toolroom reactive or proactive?

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)