Automation

Injection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

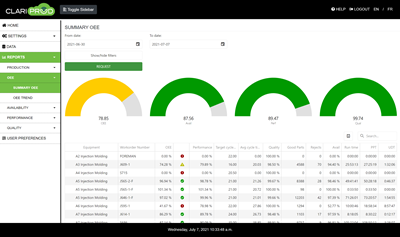

WatchReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

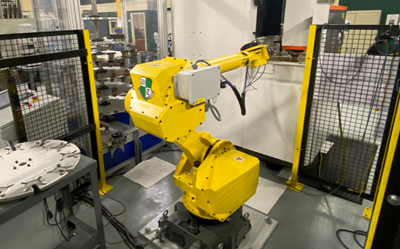

Read MoreMove Into Automation Adds to Mold Building Quality, Competitiveness

NPE2024: Cavalier Tool is showcasing its multiphase shift into more automated processes for lifters, inserts and slides manufacturing, in addition to giving attendees a chance to step inside a mold.

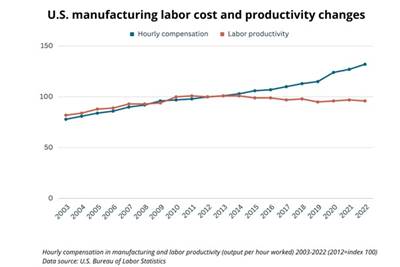

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreOutlook for Automation in 2024

I want to share an article I found that discusses the reasons manufacturers should adopt automation in 2024 as a strategic response to global uncertainties, reshoring requirements, labor shortages and the pursuit of increased productivity.

Read MoreAutomation-Ready Nondestructive Inspection CT Systems

Nikon Metrology has launched VOXLS 30 C 225, 30 C 320 and 30 C 450 inspection models designed for automated operations across the production sector.

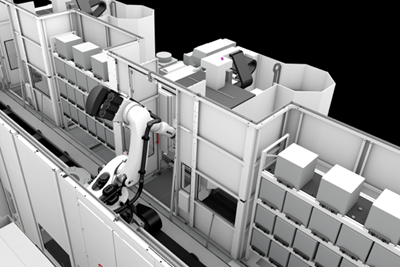

Read MoreHow to Build the Right Automation System

Seven considerations when developing an automation solution for your customers.

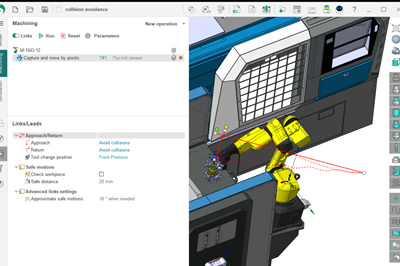

Read MoreRobotic Programming Suite Introduces Enhanced Functionalities, Improvements

SprutCAM X, an all-in-one CAD/CAM/OLP software suite for complex and creative robot tasks, has updated its Collision Avoidance feature, amongst others for a more streamlined experience.

Read More3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

Read MoreMMT Chat: Key Principles of an Automated System

PFAFF Molds develops its automated systems to address key customer pain points – such as high worker turnover, rising costs, volume fluctuation and sustainability.

Watch