Automation

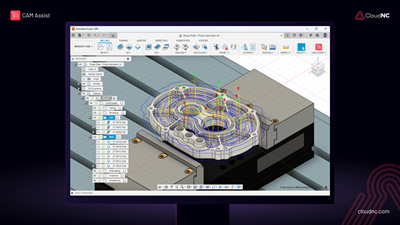

AI-Aided Software Accelerates CAM Programming Time by 80%

CAM Assist from CloudNC automatically generates professional machining strategies in seconds, enabling U.S. manufacturers to be more productive, reducing lead times and eliminating the skills gap.

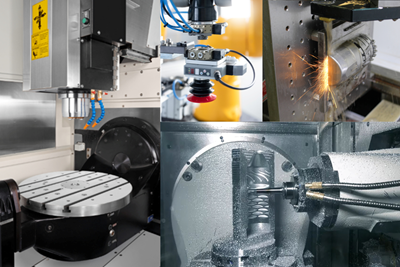

Read MoreDiscover Metalworking Technologies Targeted to Mold Shops

What EDM, automation and machining technologies are currently available to the mold manufacturing industry? MMT has compiled a list of some of the latest.

Read MoreRobotic Toolchangers Automate Mold Production

Stäubli’s robotic toolchanging system offerings reduce the risk of error, save time and improve overall quality and consistency of moldmaking.

Read MoreCompact Robotic Palletizer Easily Automates Packaging Process

The Cube cell, complete with a KUKA KR50-R2500 robot, is targeted for small- and medium-sized businesses looking to automate the palletization of their end product.

Read MoreHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

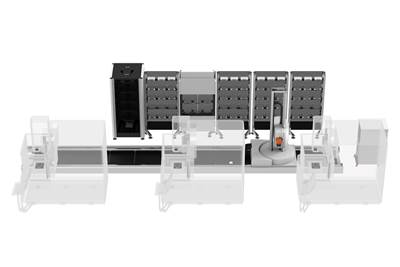

Read MoreAutomation System Loads up Expandability, Scalability and Precision for Moldmakers

The expandable, scalable, open architecture of the System 3R Transformer system by GF Machining Solutions permits integration of various technologies to optimize mold machining operations and meet any facility’s requirements.

Read MoreDigital Customer Platform Expands Automation Convenience, Support

KUKA introduces a relaunched my.KUKA.com platform, offering expanded user interface and product finding capabilities for an intuitive, easy-to-use destination for in-depth customer resources and support.

Read MoreWhat Does Automation Look Like in Moldmaking?

There are a variety of technologies and products that can help optimize and automate the manufacturing processes involved in moldmaking.

Read MoreRobotic Metal 3D Printer Automates, Augments AM, Repair and Cladding

The ready-to-use Meltio Robot Cell plug-and-play solution integrates Meltio’s metal 3D printing technology with a robotic arm for safe, reliable and automated 3D printing.

Read MoreMoldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

Watch