Outlook for Automation in 2024

I want to share an article I found that discusses the reasons manufacturers should adopt automation in 2024 as a strategic response to global uncertainties, reshoring requirements, labor shortages and the pursuit of increased productivity.

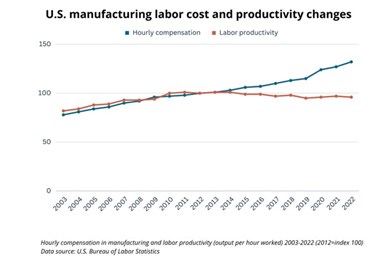

Wage and productivity gains in US manufacturing are not on par. Over the past ten years, hourly compensation grew by 30%, while labor productivity fell by 5%. The trend highlights a growing need for solutions to boost productivity. Photo Credit: U.S. Bureau of Labor Statistics

Wage and productivity gains in US manufacturing are not on par. Over the past ten years, hourly compensation grew by 30%, while labor productivity fell by 5%. The trend highlights a growing need for solutions to boost productivity. Photo Credit: U.S. Bureau of Labor StatisticsThe authors, Søren Peters (CEO) and Mette Klausen (Platform Director) of HowToRobot, highlight key factors that make automation essential in the current business environment.

To summarize, the year 2023 witnessed global political unrest, supply chain disruptions, and rising interest rates, leading many businesses to delay investments and save cash. The uncertainty is expected to persist in 2024, with The Economist describing it as a "second cold war" and "multipolar disorder." In response, businesses are likely to make strategic investments, with automation emerging as a crucial area.

One major driver for automation is the need to reduce supply chain dependencies. Political events have disrupted global supply chains, prompting businesses to consider reshoring production. Automation plays a key role in moving production closer to OEMs, helping offset growing labor expenses associated with reshoring.

Labor shortages have contributed to record robot sales. Despite some easing in 2023, the gap between labor supply and demand remains, with structural issues in both the U.S. and Europe. As the number of workers retiring accelerates and fewer young people enter the workforce, automation becomes crucial to ensure business continuity. Unions are recognizing the role of automation in safeguarding jobs in the long run.

Productivity remains a driving force behind automation, as businesses aim to produce more at a lower cost. The article highlights the growing pressure on manufacturers to advance productivity, given the substantial rise in labor costs. Businesses are setting clear performance goals for automation solutions, leading to a more rational and practical dialogue between buyers and sellers in the robotics market.

The authors note the maturing robotics market, with an increased focus on practical considerations and the emergence of sourcing platforms to facilitate automation adoption.

Check out the full article here.

Related Content

-

Quality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

-

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

-

Overcoming Barriers to Automation Integration in Precision Moldmaking

It’s easy to imagine the advantages automation offers the moldmaking process, but it's challenging to change one’s mindset, develop a plan and invest.

.jpg;maxWidth=300;quality=90)