Videos

Scenes from Amerimold 2018, Part 2—Education!

MMT brings readers yet another look at Amerimold 2018. This time, the focus is on education via our Tech Talks, technology demos and more.

WatchThe Hidden Complexities of Optimized Roughing

Consider these factors for developing an optimal process using optimized roughing strategies.

Watch2018 Leadtime Leader Award Winner: Maximum Mold Group

Strategic acquisitions and diversified capabilities combined with a can-do, inclusive culture take this mold manufacturer to new heights.

WatchThe Manufacturing Alliance NPE2018: The Wrap Up Show

Christina Fuges, Cyndi Kustush and Barbara Schulz of MoldMaking Technology take a look back with The Manufacturing Alliance at the technology and trends they saw during their five days at NPE2018.

WatchNPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

WatchCelebration Event to Highlight Emerging Technologies

Autodesk’s Smart Manufacturing Celebration is on April 26 and 27, 2018, in Grand Rapids, Michigan.

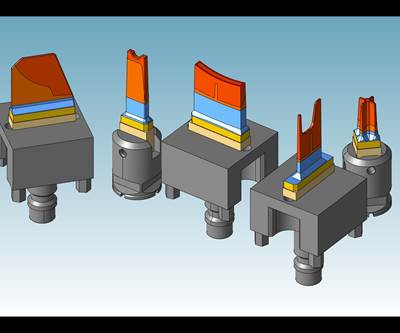

WatchCAD Software Automates Die-Sinking Electrode Manufacturing

Advanced CAD/CAM software with dedicated electrode design capabilities greatly reduces electrode design, modeling and manufacturing time.

WatchDecision Drivers for Selecting Solid Carbide or Indexable Tools

Criteria like machine tool spindle power, workpiece geometry and material, CAD/CAM for CNC programming and fixturing drive rough milling cutter selection.

WatchBest Practices in Tooling for Ultimate Molding Success

Active project participation and management using a systems-engineering approach streamlines efforts and optimizes opportunities for molding success.

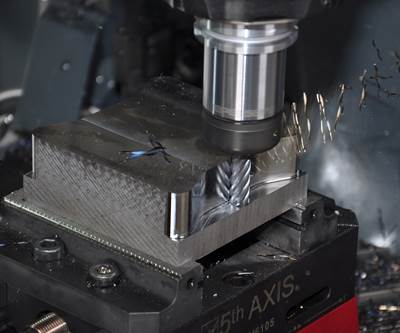

WatchAccelerated Machining for Precipitation Hardness Stainless Steel

A carbide cutting tool manufacturer partnered with a machine tool supplier to demonstrate accelerated machining of precipitation hardness stainless steel, such as 15-5 PH stainless steel.

WatchMilling and EDM Automation Reshape Summit Tooling’s Mold Operations

Summit Tooling President Dan Martin credits the capability to run unattended machining 24/7 to the partnership that his company built with Makino.

WatchWhy You Need a Tool Presetter

Reduce machine idle time with fast, accurate, repeatable, offline cutting tool measurements.

Watch