Accelerated Machining for Precipitation Hardness Stainless Steel

A carbide cutting tool manufacturer partnered with a machine tool supplier to demonstrate accelerated machining of precipitation hardness stainless steel, such as 15-5 PH stainless steel.

Carbide cutting tool manufacturer Tungaloy America Inc. recently partnered with machine tool supplier Toyoda Americas Corp. to showcase its latest offerings designed for accelerated machining of precipitation hardness stainless steel. The lunch learning seminar was held at Toyoda’s Arlington Heights, Illinois, facility.

Machining Challenges for 15-5 PH Stainless Steel

During the seminar, the material referenced was 15-5 PH stainless steel. A growing market focus on higher material performance and functionality is making metal machining even more challenging, according to Tungaloy. A premature, catastrophic tool failure is a typical failure mode in machining difficult-to-cut exotic metals like 15-5 PH stainless steel due to heat generated during machining.

Kedar Bhagath, Tungaloy America’s chief technical officer, led the seminar, which also included an on-site demonstration of each of the five featured cutting tools using Toyoda’s high-speed FH630SX-I 8,000 RPM horizontal machining center with dual drive motors.

Bhagath explained that precipitation hardening steels are those that contain chromium and nickel, using their distinct properties to create, through low-temperature heat treatment, a high-strength steel material. 15-5 is a variation on the older, corrosion-resistant 17-4 chromium-nickel-copper PH stainless steel, but with greater toughness. He then reviewed some of the more vexing challenges encountered when machining high-temperature materials like 15-5. These include:

- Thermal cracking due to corrosion

- Notch wear

- Lubricity, which is needed to reduce material build-up but can cause unwanted contamination in some instances

- Imbalanced cutting forces (it is necessary to maintain balance to avoid vibration, so in addition to stronger, more rigid cutting tools, good machine tools are a must).

Basically, Bhagath says that materials like 15-5 must be machined using specific geometry and edge prep to avoid becoming gummy, as is characteristic, due to high heat generated during high-speed machining processes. He introduced several cutting tools developed by Tungaloy that have been designed specifically to boost productivity when working with difficult-to-machine materials.

See it in Action

To see the five featured cutting tools in action is ideal, and highly recommended, but the next best thing is to view videos of each in action. This blog will present videos, compliments of Tungaloy, following a basic description of each cutting tool featured and benefits delivered.

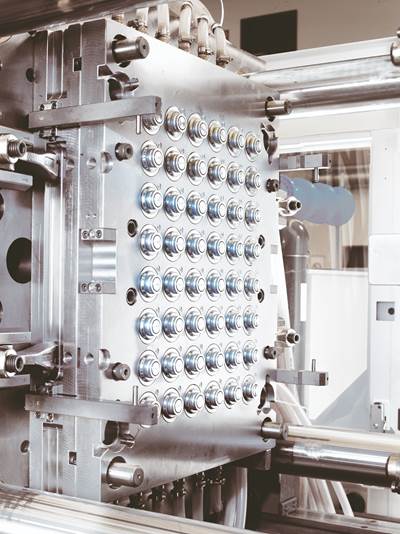

Four-inch DoTriple-Mill is a face-milling cutter that features three different, double-sided inserts in one. What’s unique here is that it has “dovetail” clamping to ensure stability, especially when performing high-speed machining of high-temp materials.

The 2.63-inch TungDrillBig is a large-diameter, adjustable drill that reduces the number of drills required. The drill body comes in five sizes . It gives a well-balanced cutting force and rigidity, and offers TDS or TDX cartridge options.

The 2.0-inch High-feed mill called DoFeed is ideal for high-feed milling, plunging, enlarging holes, slotting, drilling, shoulder milling, general machining and mold machining. It features double-sided inserts with four positive cutting edges and a low cutting-force design. Tungaloy says it is the only cutting tool to offer a wiper insert for high-feed machining to achieve better surface finishes and eliminate semi-finishing operations.

Tungaloy’s Tung-Tri shoulder milling cutter features an anti-chatter design. The company demoed a 1.5-inch sized end mill at Toyoda to show its three-cutting-edge insert with large rake angle on cutting edge that stabilizes the cutting operation as it evacuates chips smoothly and performs large depths of cut.

Finally, the newly expanded TungForce-Rec line of square shoulder milling endmills were demonstrated. Bhagath described them as having wider support below the insert for better and stronger accuracy and stability. These small-diameter shoulder mills have unique, V-shaped insert bottoms so the inserts do not move, reducing shear forces on the screw. 2 types of insert geometries allow versatility of materials that can be machined, including steel, stainless, cast iron, aluminum and heat resistant superalloys.

Related Content

Cutting Tools: Technology to Make Your Process Easier

Having the right cutting tool technology for moldmaking is a crucial component for efficiency and cost-effectiveness.

Read MoreHow to Overcome Cutting Tool Vibration

Advanced indexable milling cutting tool design provides secure, predictable machining, increased metal removal rates, reduced cycle times and fast changeovers.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreRead Next

Selection Process for Stainless Mold Steels

Successful production of plastic components associated with the extrusion, injection and compression molding greatly depends on the mold material selection.

Read MoreThree Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

Read MoreSteel Choice Matters for Corrosion Resistance

A free-machining stainless steel faces the extremely corrosive injection molding environment head on, improving machinability and stability.

Read More