Engineer

2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

Read MoreMMT's Most-Viewed Case Studies in 2024

Did you miss any of MoldMaking Technology’s most-viewed case studies from 2024? Now’s your chance to dive into these trending topics.

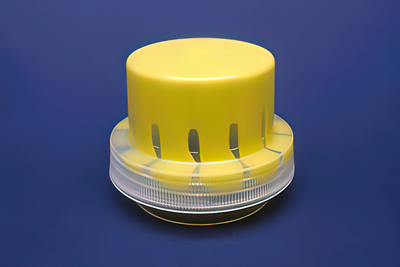

Read MoreOptimizing Adaptive Sensor Feedback For Low-Pressure Molding

MD&M West 2025: Moldex 3D highlights its adaptive sensor for evaluating and optimizing feedback via innovative processes with simulation.

Read MoreTop 10 Engineering Content From 2024

Peruse the most-viewed engineering content that you may have missed this past year from MoldMaking Technology! Discover the next software to best benefit your moldmaking capabilties – from data management to design and manufacturing software, we have you covered.

Read MoreCNC Control Offers Moldmaking Precision and Process Reliability

MD&M West 2025: Heidenhain Corp. highlights its TNC7 CNC control, engineered to tackle the specific challenges of moldmaking with a focus on precision, efficiency and flexibility.

Read More2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read More2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreMoldMaking Technology's Most-Viewed Content of 2024

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read MoreMMT Chats: The Rise of Tooling Digitalization

MoldMaking Technology Editorial Director Christina Fuges chats with Bob Vancoillie with the Consumer Division of Johnson & Johnson about OEM corporate initiatives for digitizing tooling.

WatchHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read More

.jpg;maxWidth=300;quality=90)