Turning

Hydraulic Fluid Reduces Energy Consumption by Eight Percent

An energy-efficient hydraulic fluid has been developed for use with CNC machines that features low-deposit forming tendencies, provides equipment protection and can extend oil maintenance intervals.

Read MoreHigh Speed Balancing Act

Think you’re using toolholders properly balanced for high-speed machining? Well, you may have to think again.

Read MoreWhat Driven at the Center of Gravity Means To Your Machine Tool

Getting to the bottom of the technology that is built into today’s machining centers will help you select the best machine tool for your application.

Read MoreLearn to Compete with Negative-Shape Machining

Moldmakers can reduce costs and increase throughput with a high-technology approach.

Read MoreMatch Cutting Tools To Machine for Maximum Efficiency

A large range of tooling enables moldmakers to match cutting tool to machine and part geometry, resulting in maximum metal removal rates and productivity for roughing applications on conventional and high-speed machining centers.

Read MoreEquipment Leasing: A Popular Alternative to Buying

Leasing equipment provides moldmakers with more purchasing opportunities during tough financial times.

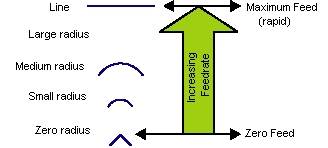

Read MoreBecoming More Accurate With Speed

By adding optimization software to their machining, moldmakers will be able to produce better quality parts with better accuracy.

Read MoreThe Need for Speed

The trend for higher speeds in machining technology has moldmakers scrambling for the cash to purchase this equipment and the subsequent training to bring them "up to speed".

Read More

.jpg;maxWidth=300;quality=90)