Choosing and Using The Right Mold Cleaners, Part 2

Knowing the requirements of offline and online cleaners yields cleaner molds.

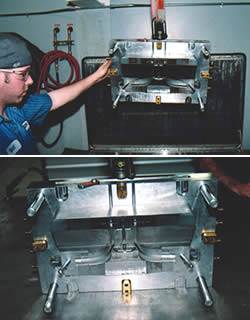

Mold cleaning is required offline when the mold is on the bench and cold (room temperature); and, online when the mold is in the press and warm. Because of temperature differences, the cleaning solvents may have different degrees of effectiveness. Solvents that work well on the bench and evaporate at a convenient rate are usually flashed off rapidly on a hot mold and are not in contact long enough to do much cleaning. Solvents that work well at higher temperatures are less aggressive and effective at room temperature.

They take longer to evaporate or may have to be wiped off. Using the wrong cleaner may result in poor cleaning or excessive time to accomplish the job. Requirements of offline cleaners are to dissolve resins, grease, oil, mold release and rust, and to have a very fast evaporation rate. The best cleaners for this have traditionally been chlorinated hydrocarbons, but a recently released EPA review on these chlorinated ingredients (Trichloroethylene solvent) has cast doubt on the safety of such chemicals. New mold cleaner formulations are available that have eliminated these chlorinated solvents without sacrificing product performance or resulting in a higher priced product. These non-chlorinated hydrocarbons as well as napthas are effective mold cleaners.

They readily dissolve greases and oils by flushing the mold with a heavy spray from top to bottom. Mold release and resin build-up may require scrubbing the mold with a cloth saturated with a cleaner. New technology involves a pre-saturated mold cleaning wipes that are generally packaged in a canister similar to what would be found with baby wipes, which results in guaranteed sterile, lint-free, clean cloths ideal for precision cleaning; pre-saturation with the ideal amount of cleaning solvent included; and, easy-to-use, non-hazardous disposal.

A final option for offline cleaning is the use of a mold polish and cleaning compound, which are typically used in paste form and require manual application/removal. The typical mold polishing

paste contains a combination of cleaning solvents and mild abrasives designed to aid with the removal of all contaminants from the mold surface. An added benefit of using such a polishing paste is the resulting sheen or luster that is left on the mold surface. Such a finish serves as a natural lubricant and release, thus minimizing the need for a mold release to be used later once the mold is put back into production.

Online cleaners are used to remove mold release build-up, plate out of resins and light rusting of the mold. Often molds get plate out, which is due to the adhesion of resins or fire-retardant materials. Such build-up must be chemically removed from the mold surface in order to minimize potential part deformation. A resin-removing product can chemically work to break down the material and aid with the removal of the unwanted resin from the mold surface.

As a general rule, cleaning solvents used on a warm or hot mold should be much slower evaporating. This allows for the chemicals to remain on the mold surface for longer periods of

time, thus maximizing the cleaning potential.

Related Content

What You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreRead Next

Streamline Your Mold Cleaning Process

Ultrasonics can help your shop reduce labor costs and product waste while boosting efficiency and product quality.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More