Selective Plating of Mold Surfaces Extends Life and Reduces Repair Costs

Wear and tear on molds and the need for repairs are a regular cost of doing business for plastic and metal molders. However, costs can be drastically reduced through selective plating without removing the tooling from a machine.

Damage to molds and related tooling for plastic and metal parts seems to be inevitable due to foreign objects getting into mold cavities, acidic corrosion caused by some plastics, and other causes of wear and tear. In some cases, small flaws in new mold tooling causes higher than acceptable scrap rates. This can mean tearing down the equipment to remove the mold and sending it out for repairs using various resurfacing and replating methods. However, with in-situ selective plating techniques, mold surfaces can often be repaired without taking the mold out of the machine. This greatly reduces repair costs. The end result is reduced rework and scrap rate costs.

Selective Plating Process

Mold/die costs vary widely depending on size, materials and origin. With costs ranging from tens of thousands of dollars up to millions for large automotive part dies, the last thing a producer wants to do is buy new tooling. Just the cost of removing a mold from the machine for outside repair is substantial, and the cost of lost production is greater still. This makes typical in-situ plating repairs for a one-day job a very attractive option. These costs vary depending on the size and depth of the mold area needing repair.

The general approach for selective plating repairs is:

• Dish out the repair area to create the appropriate depth-to-diameter ratio (typically this is about a 1:7 ratio to get rid of any sharp corners)

• Apply cleaning and surface treatment chemicals to prepare for plating

• Use selective plating to fill the depression with soft metal material (often copper)

• Then selectively plate with a harder metal that adheres well to the mold and fill material

• Have a mold repair technician do final dimensioning for the required finish and sizing

As a general rule, defect depths of up to about 0.060” are good candidates for this type of repair. Greater depths may be possible if there are cracks and crevices that can first be repaired through other techniques like welding and preliminary grinding. However, use of those techniques with the mold in the machine may or may not be practical.

If a mold has a lot of corrosion, scratches and other small surface flaws that result in a poor finish on the molded part, the temptation may be to remove the tooling and send it out for tank electroplating. However, selective plating can take care of these flaws without extensive masking, and is significantly faster than tank electroplating.

Selective plating equipment is portable, enabling the operator to meet plating and build-up requirements wherever they arise. This flexibility is an important cost and time saver. It minimizes dismantling, downtime, turnaround delays and shipping charges usually associated with sending parts out to be plated.

Selective Plating Capabilities

Selective plating techniques were first developed in the late 1930s, but have been refined with more modern plating materials and equipment today. Usually shops opt for having a specialist come to their plant and do this type of repair. Even in plants doing high-volume production, an investment in brush plating equipment and training may be difficult to justify.

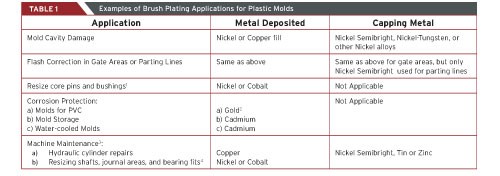

Dozens of pure metal and alloy solutions are available for use in brush plating to accommodate different mold metals and finishes. These solutions typically have higher metal content than those used in tank plating. Deposits can be produced that are hard, fine grained, very low in porosity, have low residual stress and are not prone to hydrogen embrittlement. Electropolishing and application of wear-resistant coatings to the mold surface can also be accomplished using the same techniques. Examples of plastic mold plating applications are listed in Table 1.

As shown in Table 1, selective plating can solve various mold problems and some associated with other parts of a plastic molding machine. Nickel and cobalt are excellent choices for selective deposition to resize core pins and bushings, often without finish machining. These two materials have good toughness characteristics, in addition to excellent wear resistance. If a harder surface is required, nickel-tungsten, nickel-cobalt and cobalt-tungsten alloys may be selectively deposited in a hardness range of Rockwell C 47 to 60.

The preparatory process used depends on the base material of the mold and any plating from prior processing that may be present. This process can include solutions for cleaning, etching, desmutting, activating and preplating. In all cases, preparatory and plating solutions are applied with a handheld plating tool wrapped with an absorbent cover material saturated with the solution. The mold is attached to the ground lead of a DC power supply, and the plating tool is connected to the positive lead to complete the circuit.

Summary

Selective brush plating is a cost-effective mold repair technique for a broad array of mold surfaces. It can be accomplished without removing the mold from production machinery, and can often be accomplished in a matter of hours.

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreUltra-Fast Femtosecond Laser Texturing Helps Produce EV Lighting Lens Molds

Edge-lighting lens patterns present moldmaking challenges that ultra-fast femtosecond laser texturing technology can overcome.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More