Industry 40

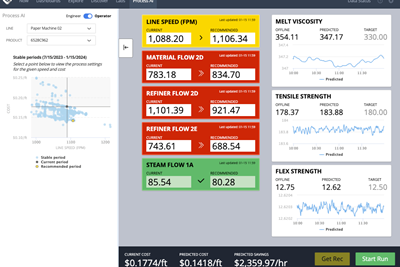

Use AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

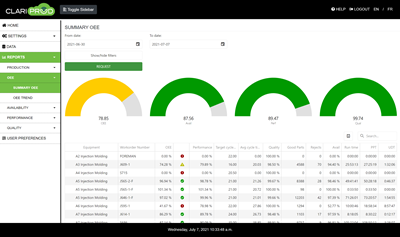

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreDigital Platform Enables Remote Machine Troubleshooting

GF Machining Solutions’ My rConnect provides a virtual link between a machine and the company’s service and support team, giving live and historical data without the need to travel to a customer’s shop.

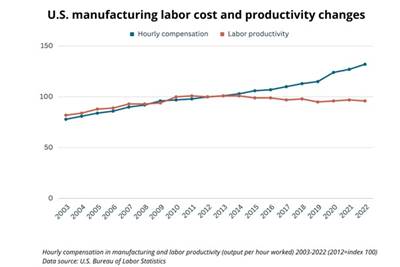

Read MoreOutlook for Automation in 2024

I want to share an article I found that discusses the reasons manufacturers should adopt automation in 2024 as a strategic response to global uncertainties, reshoring requirements, labor shortages and the pursuit of increased productivity.

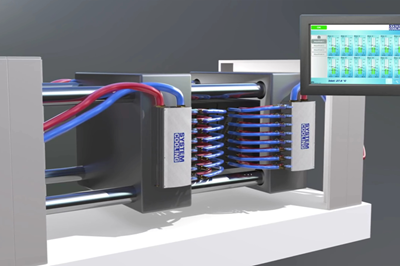

Read MoreIntegrated RFID Achieves Hot Half Hot Runner System Digitalization

Newly ordered hot halves from Hasco are now equipped with RFID-chipped Mould Tags to enable reliable and direction access to all injection mold unit information.

Read MoreHow to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

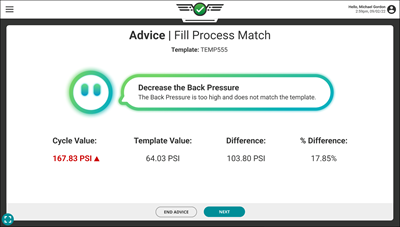

Read MoreAI Augments Injection Molding Process Control System

MAX, a new process advising feature added to RJG’s Copilot system, is engineered to help troubleshoot and optimize the injection molding process and addresses industry skill gap.

WatchMMT Chats: Predictable Manufacturing and Incremental Gains Can Transform Moldmaking

MoldMaking Technology Editorial Director Christina Fuges catches up with the president of Eden Tool and Eden Manufacturing, Dave Tomic. We talk about predictable performance in moldmaking and the value of small incremental gains in an organization versus big change via disruptive technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Watch5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

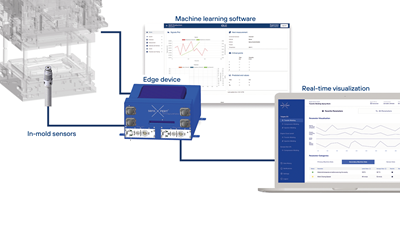

Read MoreIn-Mold Solution Drives Dynamic Process Optimization, Data Transparency

The sensXpert platform provides a “customer-centric” approach, enabling moldmakers and plastics processors to measure and monitor temperature and material behavior inside the mold for real-time data and full manufacturing transparency.

Watch

.jpg;maxWidth=300;quality=90)