Five Axis

DMG/Mori-Seiki Hosts Innovation Days

Leading machine tool manufacturer DMG/Mori-Seiki welcomed customers, partners, employees, and other industry professionals to Hoffman Estates, Illinois for Innovation Days, a three-day event featuring seminars, machine demonstrations, and expert presentations, held May 3-5, 2011.

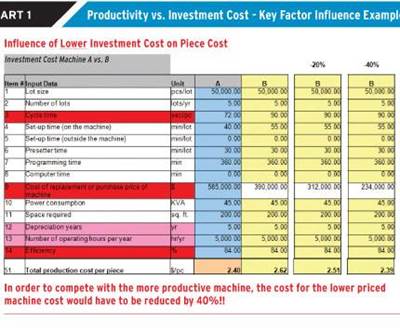

Read MoreHow to Justify New Machine Tool Technology

A look at some of the factors influencing the success of your machining center investment.

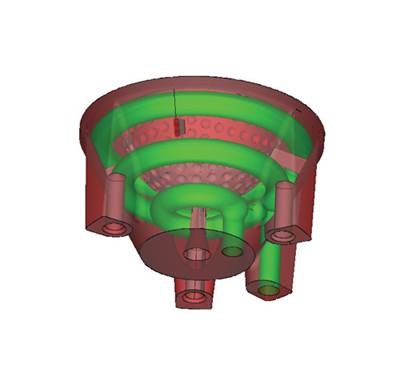

Read MoreSeamless Process Creates the Impossible Cooling Channel

A multiple-machine moldmaking process—combining DMLS, high-speed five-axis machining and EDM— produces conformal-cooled molds in a seamless automatic process.

Read MoreEquipment Retrofits Increase Shop Speeds, Feeds

Equipment retrofit perspectives from the trenches.

Read MoreDMG / Mori Seiki Launches the New X‐class Series

The X Class machine has been designed as a result of thousands of users' feedback on the popular N Series.

Read MoreHigh-Performance Machine Improves Large Automotive Mold Machining

With a new generation of automotive mold applications ahead, the VG is ashowpiece that reflects Hi-Tech Mold's dedication to future innovation.

Read MoreReinvesting in Machinery, Processes and People Adds to Bottom Line

Specializing in high precision molds with interchangeable components, RMM has supplied the industry with a wide variety of tools including, single face, stack, unscrewing, multi-material, rotary cube technologies—and considers its customers’ needs a number-one priority.

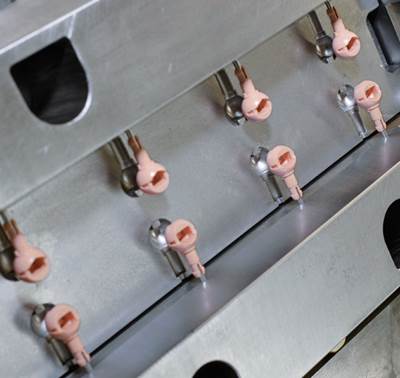

Read MoreFrom the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

Read MoreMachine Tool Expandability Through Efficient Retrofitting

Considerations for determining if retrofitting is the appropriate and economical solution for your shop.

Read More