Five Axis

Wiping the Slate Clean with a Brand-New Facility

“After the two-week transition period, we were operating smoother than we were at our previous facility.”

Read MoreMega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

WatchMold Roughing

Tolerances and finishes on the Buss Precision's molds are tailored to the specific project, but most work is held to +/-.0002 tolerance on multi-cavity components, cavity, cores and parting lines.

WatchEnhance Mold Precision by Going Five-Axis

Here’s how to manufacture large or high-precision, complex molds while maintaining efficiency.

Read MoreAutomated Hard Milling Expands Capacity, Capability

“The key to investing in new machinery is to get more work done with the same amount of people, not the same amount of work with fewer people. To accomplish this, you need automated machining capabilities that are both flexible and reliable."

Read MoreThe Right Machine Eases Moldmaker’s Transition to Five-Axis

“This new technology allows us to be more efficient, which in turn means we can take on more work and also meet the short turnaround times our customers need.”

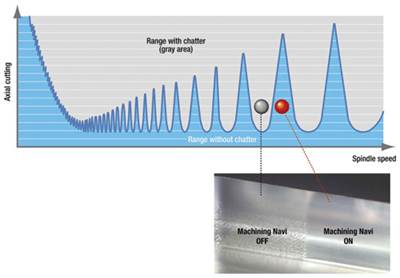

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreEliminate Chatter and Solve Finish Problems

Eliminating chatter is a great way to improve surface finish when performing CNC milling. Okuma's Machining Navi M-i detects chatter and automatically adjusts spindle speed to eliminate chatter, thus improving surface finish. This is a terrific tool for the mold/die industry.

WatchLinear Drives Increase Speed, Accuracy

Two distinctive capabilities on the new machines each have a great impact on DTE's time to market— linear drives and five axis.

Watch