FAQ

How to Hire the Right Mold Polisher

When it comes to mold polishing, every step is crucial.

Read MoreHow to Systematically Diagnose Mold Issues and Part Quality Variations

Apply fundamental plastic flow principles to troubleshoot your mold’s problems.

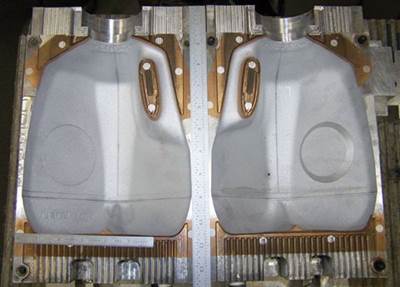

Read MoreSouth Coast Mold: Energy, Efficiency Add up to Success

South Coast Mold, Inc. (Irvine, CA) is not your typical mold shop, but a small sub-set (niche) of the broad injection mold business since its specialty is castings.

Read MoreHow to Develop Strategies For Globalization

The main challenge in dealing with any strategy for business growth is that it is interdependent with opportunities and being prepared to capitalize on them when they occur.

Read MoreFour Key Uses of Prototyping

Prototyping helps evaluate and test a design, clarify production costs, sell a product and secure patents.

Read MoreHow to Get the Most Out of Your Control

If the spindle is the heart of the machining center, the control is the brain. This article will help you explore whether it’s time to expand your brain and find new efficiencies to increase profitability.

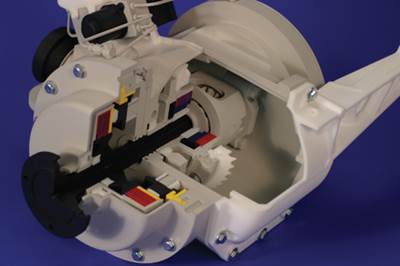

Read MorePrototyping Checklist: How to Choose

Today there are many prototyping technologies to support the full development cycle of a product from initial idea to manufacturing full-scale parts to low-volume production.

Read MoreHow to Manage Change

If there’s one word that captures the essence of what is occurring in the world today, it’s change.

Read MoreWhat Is the ROI Of 3-D Scanning?

A moldmaker wanted to re-qualify used molds to see if they needed refurbishing, and if so, where to make the corrections.

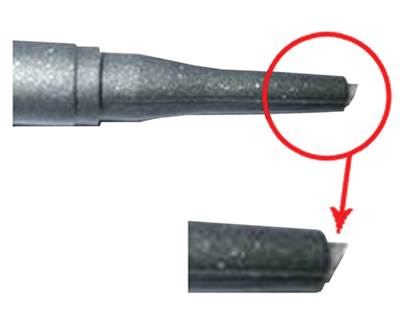

Read MoreHow to Determine The Real Cost Of Your End Mill

More often than not, the first question a moldmaker asks when presented with an end mill is, “How much does this tool cost?” For this, there is really only one answer, “I can tell you the price, but I cannot tell you the cost until you run the tool.”A higher priced tool can ultimately prove to cost much less than its lower priced counterpart.

Read More