FAQ

Popular Posts: February 2020

Catch up on these five most popular blog posts from February 2020.

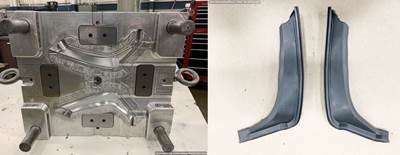

Read MoreHow to Use a Conformally Cooled Sprue Bushing to Reduce Cycle Time and Ease Cost Pressures

Use of a new conformally cooled sprue bushing helped solve Midwest Mold Services’ problem with a big sprue that was hard to cool and preventing faster ejection times.

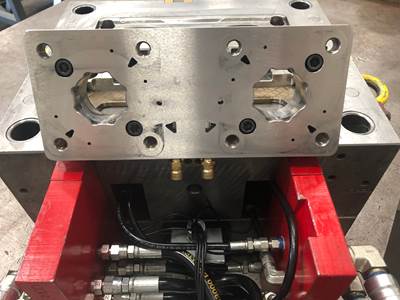

Read MoreAdditive Tooling Goes Beyond Conformally Cooled Inserts to Simplify the Mold Build Process

Three ways that additive tooling is moving past conformal cooling to bring speed and efficiency to the overall tooling process.

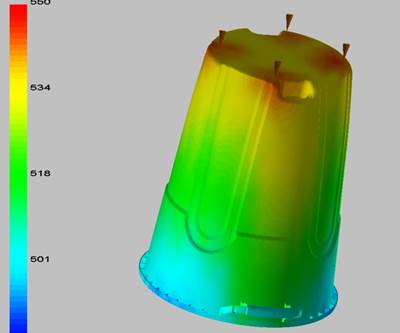

Read MoreHow to Design High-Efficiency Capabilities into an Injection Mold/Molding System

Mold builders can boost profits and part quality with expert analysis and optimization techniques.

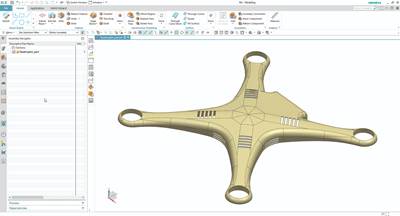

Read MoreHow to Pre-Estimate Tooling Costs

The right costing software can help to improve mold quoting and production.

Read MoreHow to Improve the Flow of Mold Repair and Engineering Changes

A new perspective on competition, training and workflow redefines this shop’s core competency in repair and engineering changes, and charges the team toward continuous improvement.

ListenHow to Become a Better-Informed Mold Purchaser

Six questions every purchasing manager must answer to improve his or her buying skills and create more value for the company.

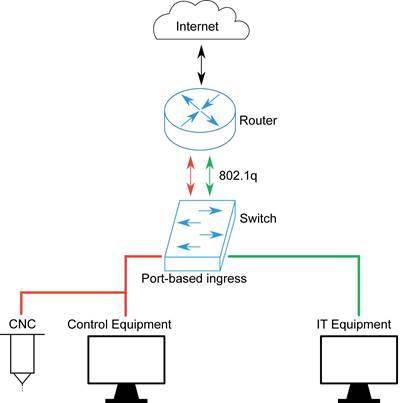

Read MoreEstablishing a Cyber-Secure Moldmaking Operation

Mold builders must understand subnetwork setup, threat and risk analysis, and support structures to protect its data.

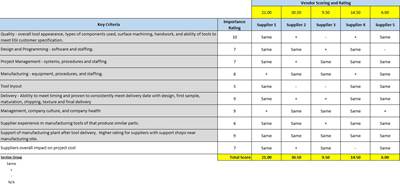

Read MoreHow to Ensure Quality Offshore Tooling

When working with a foreign mold builder provide clear expectations and conduct comprehensive reviews throughout the moldmaking process to ensure a robust mold.

Read MoreHow to Improve Tooling Supply Chain Transparency

An automated tooling supply chain management system will maximize efficiency, minimize risk and improve tooling supply chain transparency.

Read More