Popular Posts: February 2020

Catch up on these five most popular blog posts from February 2020.

It’s the end of the month, so that means it’s time to look back and reflect on the five most popular blog posts from February. These are the most viewed articles that readers like you have read and enjoyed, so don’t miss out on what everyone else is reading. Take a look and learn some more about what’s going on in the moldmaking community.

Revisiting Some Hot Runner Fundamentals

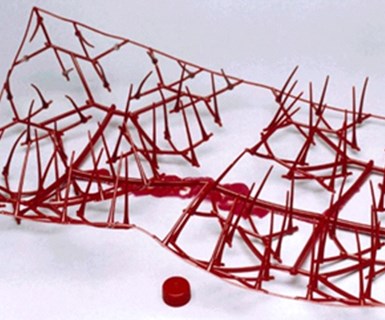

Very intelligent and experienced people in the plastics industry frequently ask for hot runner basics because although they know that a hot runner is a critical component in the injection molding process, some don’t understand what it does or how it works. Remember those plastic model kits you put together as a kid? The excess plastic that held those tiny components for the model in place is called a cold runner, and it is essentially scrapped plastic. Cold runners created during industrial production are very much like those models but on a much larger scale. When you consider the cost of resin, cold runners can be an expensive prospect because of the unwanted scrap plastic they produce.

Read the complete article here.

How to Correctly Size a Hydraulic Cylinder

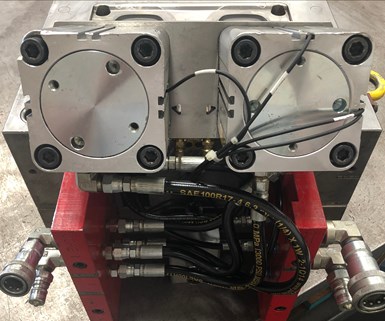

In order to correctly size a hydraulic cylinder on a mold, follow these steps.

- Train the mold designer to understand the potential maximum plastics pressures, so he/she can accurately calculate the plastics pressures that the cavity surface area will have on the component. Many will look only at pack/hold pressures, when peak plastics pressures must be considered. Also, do not solely base it off the material being used, as there are factors that can drastically impact pressures. If you are unsure then round it up. Note, if you want a robust tool and process then do not ever round it down. Once you have determined the maximum plastics pressures, the rest is easy.

- Accurately calculate the cavity surface that is on the surface area of the component. Then multiply that number by the maximum plastics pressure we discussed. The result will be the required pressure for designing your cylinder.

Read the complete article here.

Related Content

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)