Engineer

How to Use Servos and Sensors to Advance Process Control

A servo and sensor combination that makes the mold the machine presents opportunities to advance process control.

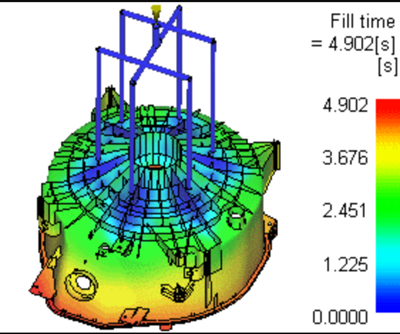

Read MoreMoldflow Analysis Solves Part Design Concerns

CAE Services uses Moldflow to analyze, identify and solve part design or warpage related concerns before cutting steel.

Read MoreVIDEO: 2020 Leadtime Leader Winner Shares Business Strategies with CNC Machine Shops

Emily Probst, Senior Editor with Modern Machine Shop reached out to me to chat about our 2020 Leadtime Leader Winner Precise Tooling Solutions to learn about key business aspects of this winning specialty manufacturer to share with her CNC machine shop readers.

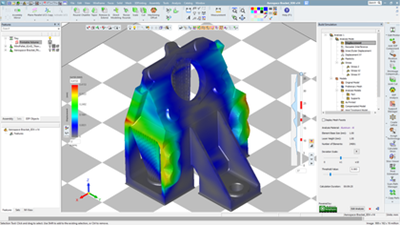

Watch5 Ways to Cut Programming Time

Steps mold builders can take to reduce programming times and improve machining processes.

Read MoreFREE ON DEMAND WEBINAR: Reduce Delivery Time and Increase Mold Quality With The Right CAD/CAM Solution

Learn how a dedicated integrated CAD/CAM solution can enable mold builders to increase productivity and deliver high-quality tools of any complexity and size in record time.

Read MoreSoftware Add-On Streamlines Design for Additive Manufacturing Cycle

3D Systems launches its latest software solution 3DXpert for SolidWorks 15, which prepares and optimizes users’ designs for additive manufacturing.

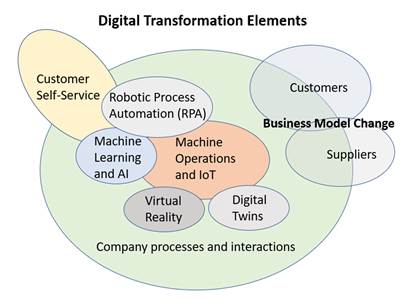

Read MoreUnderstanding and Achieving Digital Transformation

A five-step plan for identifying the business objectives and employing digital transformation as an ongoing process for improvement.

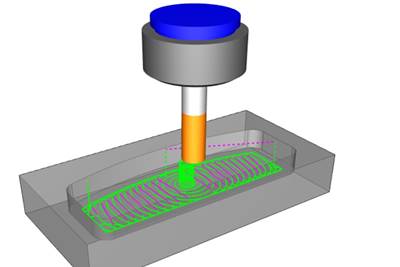

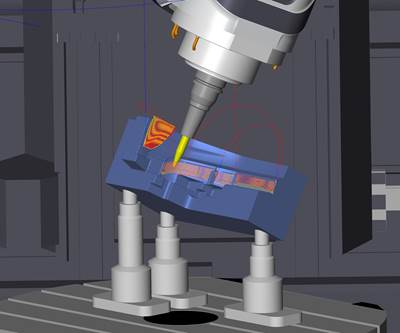

Read MoreOptimized Virtual Machining Enhances Mold Manufacturing

Virtual machining programs simulate computed tool paths as well as optimize machine tool capabilities and constraints, adding value to the computed tool paths.

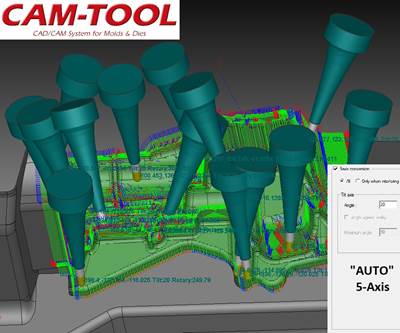

Read MoreSoftware Decreases Movement for Smoother, More Accurate Tool Paths

Cam-Tool by CGS North America, Inc. has improved its simultaneous five-axis conversion (auto) function. The process has been updated to decrease movement of extra axis when unnecessary.

Read MoreHow to Take Advantage of AI for Machine Monitoring

Artificial intelligence (AI) can help shops reduce preventative maintenance costs and increase production and efficiency gains.

Read More