Design & Mfg. Software

Conquering CAD/CAM Challenges

Leading software manufacturers and suppliers reveal how moldmakers can maximize efficiencies using the latest CAD/CAM equipment so they can program and cut complex molds in less time than ever before.

Read MoreMaking the Transition to High Performance Machining Techniques

Implementing HPM techniques—such as hard milling—into component production can be straightforward with the correct process and other considerations

Read MoreThe Key to Up-Front Mold Design

By involving the tool designer, builder and molder early in product development, you can reduce turnaround time by weeks or even months, shave weeks off the mold construction cycle and reduce costs by eliminating potential product design troubles.

Read MoreMore Thoughts on Moldmaking in Mexico

One Mexican moldmaker believes that there is a good opportunity for American moldmakers in Mexico.

Read MoreBreaking the Mold in Mold Development

Integrated analysis capabilities streamline mold design.

Read MoreAdvancing Mold Performance Using Hot Runner Technology

A quality hot runner system is one of the more important enhancements you can incorporate into a mold to improve molded part quality, reduce production times and remain price competitive.

Read MoreNew Software Makes Faster, Better, Cheaper a Reality

With a new CAM package a moldmaker/molder can now receive a job in digital format and actually cut metal before it even outputs drawings.

Read MoreRigorous Mold Tryout: Do Your Homework

If moldmakers strive to understand how an end user will use the mold, they will help their customers become more profitable and more confident in the shop’s abilities leading to a strong partnership.

Read MoreHot Stuff!

Advances in valve gating technologies and improved efficiencies heat up the hot runner market in 2005.

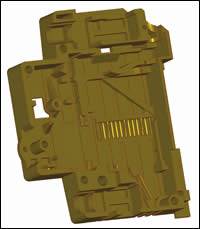

Read MoreMoldmaking in 3-D

Laser scanning helps moldmakers to improve reverse engineering and inspection tasks for their molds.

Read More