Design & Mfg. Software

NyproMold: From Art To Part and Everywhere in Between

This moldmaker’s humble beginnings as a prototype tool builder have expanded to include mold concept to completion in a number of markets.

Read MoreTooling for Closed-Molded, Low-Pressure Injection Molding Reduces Costs and Cycle Time

Floating mold technology, developed, commercialized and patented by VEC Technology, L.L.C. (Greenville, PA)—a complete systems solution.

Read MoreTools with Melt Mixing Technology Help Improve Part Quality and Productivity

Delivering a hot runner mold package that ensures melt homogeneity provides mold shops with a competitive advantage.

Read MoreThe Design Consultant Option to Better Designs and Leadtimes

Tips and guidelines for establishing healthy and profitable relationships with design consultants.

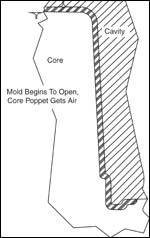

Read MoreHow Tool Design Changes with the I.C.E. Process

Mold design will change as incremental cavity ejection is used in the molding process—which includes draft angles, finishes, undercuts, stresses, cycle time and quality.

Read MoreIt’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

Read MoreModular Mold Shell Design Increases Bottle Configuration’s Flexibility

In the beverage industry, bottle producers have been focusing on hotfill and heatset bottle applications such as juices, sports drinks, sauces, etc.

Read MoreCAD Interoperability: Its Costs to Mold Design and Mfg

An industry survey reveals some real data on how CAD interoperability is affecting mold shops.

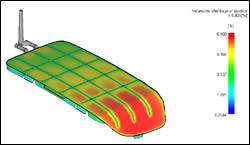

Read MoreComplete Mold Filling Analysis Helps with Automotive Design Challenges

Intier Automotive relies on CAE consulting for automotive design and innovation.

Read More