Build

How to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

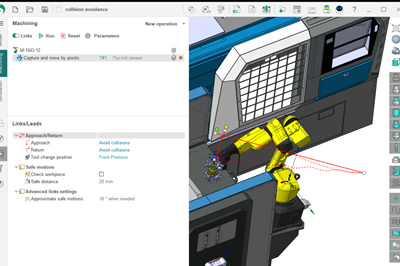

Read MoreRobotic Programming Suite Introduces Enhanced Functionalities, Improvements

SprutCAM X, an all-in-one CAD/CAM/OLP software suite for complex and creative robot tasks, has updated its Collision Avoidance feature, amongst others for a more streamlined experience.

Read More3D-Printed Hot Runner Nozzles Yield Consistent Temperature Profile

Monolith hot runners produced by DMS through a combination of SLS and AI, facilitate seamless integration with the mold and challenging material processing.

Read MoreMoldmakers Maximize Tooling Investments With Carbide Drill

Among West Ohio Tool’s custom PCD and carbide tooling, the EdgeX4 drill shows consistent precision, reliability and performance for holemaking.

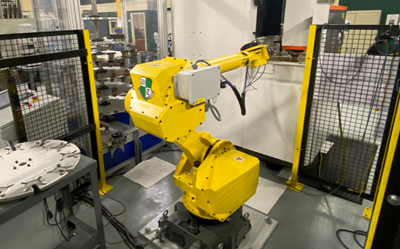

Read More3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

Read MoreIndexable Milling Platform Advances Mold and Die Capabilities

The Dapra Vapor platform features elements in body design and TRI-X2 insert geometry for higher metal removal rates and extended tool life.

WatchTool Balancing Equipment Ensures Consistent Moldmaking Results

Zoller enables balanced toolholders, tool assemblies and grinding wheels using its »toolBalancer« series, providing high-quality surface finishes and extended surface life to spindles and cutting tools.

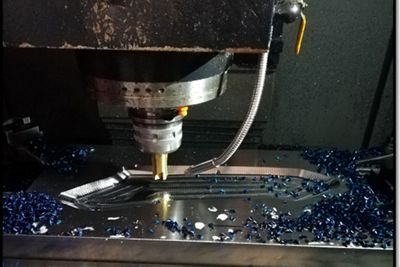

Read MoreHigh-Feed Mill Prolongs Cutting Tool Life

Keeping with its 100-year history in cutting tool design and manufacturing, M.A. Ford introduces the TuffCut HF high-feed mill.

Read MoreHigh-Feed Milling Cutter Range Benefits Moldmaking Versatility

Horn USA offers a comprehensive DAH milling tool range, including the DAH37 high-feed cutter, DAH82 and DAH84 carbide grades and the DG range.

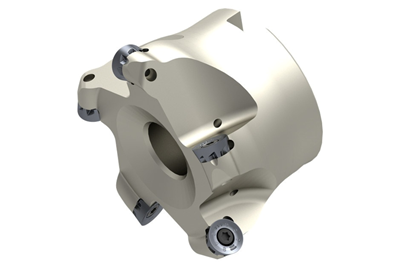

Read MoreShell Mill Supports Variety of Rough Milling Strategies

The Ceratizit MaxiMill 251 is optimal for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes.

Watch

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)