Build

Auto Nozzle Makes Minimum Quantity Lubrication Hands-Free

Minimum quantity lubrication, or MQL—also called near-dry machining—applies cutting fluid in ounces instead of gallons.

Read MoreHow to Choose the Right CNC Router

With moldmaking the focus is on injection molding or other mold types that use wire EDM or CNC machining centers to create the mold components. Your typical machining center weighs several tons and has a relatively small working envelope compared to a CNC router. The mill’s massive construction lends itself to machining rigid materials with very tight tolerances. While this type of CNC is suited for injection molding components, it isn’t always the ideal tool for the job when we broaden our scope of moldmaking and the current opportunities in the marketplace

Read MoreMold Design Tips for Automation

Automation suppliers can assist mold manufacturers with proper mold design and engineering before cutting steel for new molds. Hot runner molds, cold runner molds, box filling, insert molding, stack molds and multi-component molding are areas that can be built and managed more inexpensively, reliably and simpler.

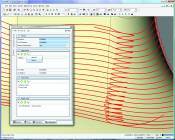

Read MoreSimplified Approach to Complex Five-Axis Machining

As multi-axis machine tools become more complex, CAM software systems must provide a more elegant way to program them.

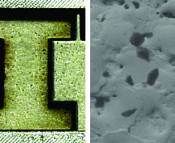

Read MoreElectrode Effect on a Quality EDM Finish

The production of fine surface finishes in the cavity does not come with the technological improvements of the EDM sinker unless an electrode material of higher quality is used.

Read MoreDirect Metal Laser Sintering vs. Conventional Tool, Part Two

In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective.

Read MoreMoldmaking Skills Give Mar-Lee a Business Boost

Molder taps tool building skills to maintain double-digit growth in high end of the market.

Read MoreAutomating from Quote to Cash

Shop floor automation tools have the ability to take the concept of the interconnected shop to the next level—giving mold manufacturers technology to transform their business, enabling them to expand into new markets and new opportunities.

Read MoreFeature-Based CNC Programming Cuts Programming Time by 25 to 75 Percent

Moldmaker switches to new programming software that auto-matically recognizes features and allows the programmer to define a process for the feature that can be repeated each time a similar feature is encountered; and, allows for more timesavings via its improved rest machining and trochoidal milling capabilities.

Read MoreSteel-Supported, Aluminum Injection Mold Frame Exhibits Durability, Strength

A mold frame that incorporates steel support pillars has all of the thermal benefits of aluminum matched with the durability of a steel mold.

Read More