Build

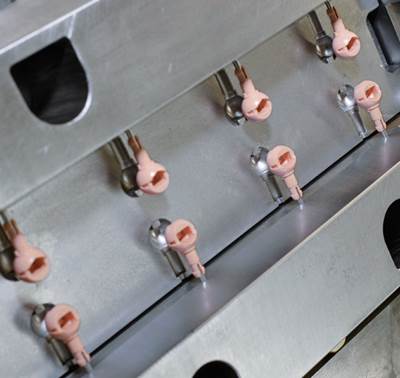

2010 Leadtime Leader Award Small Shop Winner Mold Craft, Inc.: Innovation with Automation

With an average leadtime of eight weeks, Mold Craft, Inc. (Willernie, MN)—this year’s Small Shop Leadtime Leader Award Winner—builds tight-tolerance, high-volume, multi-cavity and multi-mold projects that produce small, intricate, precision plastic parts.

Read MoreSmall Shop HM CS Tool Engineering: The Business Of Customer Service

Despite its location in Cedar Springs, MI—a state that has been hard hit by the economic downturn—CS Tool Engineering, Inc. has landed the 2010 Leadtime Leader Award Small Shop Honorable Mention by constantly investing in technology and offering its customers complete customer service with leadtimes between 10 and 12 weeks.

Read MoreAutomation: Where to Begin And End

How mold manufacturers are benefitting from today’s automation options.

Read MoreValue of Retrofitting A Machine With a Robot

How a company can do more with existing equipment and manpower.

Read MoreAutomation Division Paves Way to New Customers

Ohio-based FPM Tooling and Automation found new unconventional markets when it launched a division focused on automotive.

Read MoreFrom the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

Read MoreNew Business Opportunities: New Equipment Investment Solidifies Medical Mold Prototyping Niche

Investing in an additional high-speed machining center and converting to electric presses rather than hydraulic has allowed mold manufacturer/molder Injection Mold, Inc. (North Vernon, IN) to step up its game by speeding up already quick delivery times.

Read MoreEDM, 5-Axis Milling and Automation Technologies

GF AgieCharmilles will be demonstrating a wide variety of complementary EDM, 5-axis milling and automation technologies in its primary booth, S-8754, at IMTS 2010.

Read MoreEarly Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

Read MoreConfigured Components Help Save Time And Costs, and Maximize Efficiency

How to achieve big cost and time savings in your mold work by streamlining the mold design and ordering process. How using standard mold components can enable you to spend more time designing and building molds instead of all the components that go into them.

Read More