Build

HMC Targets Less Setup Time, Energy Consumption

INH 63 by DMG MORI integrates a variety of machining processes to ensure moldmakers are more productive, while meeting energy-efficiency goals.

Read MoreTechnology Review and Sourcing Guide 2024: Mold Materials

Building a high-quality mold requires the proper selection of appropriate mold materials. Tool steel, aluminum, copper and alloys are a just a few examples you can fin in this exclusive, online-only content that includes a supplier list for mold materials.

Read MoreFive Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.

Read MoreModular Reference System Boosts Smart Moldmaking Productivity

System 3R combines tooling automation and software, minimizes setup times and enhances productivity when moving workpieces from one process to the next.

Read MoreTechnology Review and Sourcing Guide 2024: Machining

Understanding both traditional and advanced machining techniques is vital to overcoming various dimensional and finish challenges associated with mold machining. Access more information about machining in this exclusive, online-only content, including a suppliers list, machining products and more.

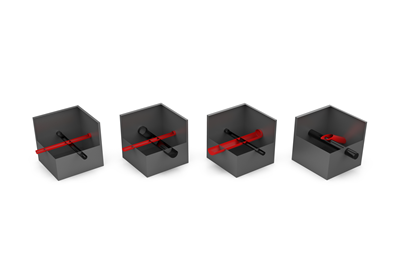

Read MoreSlide Lock-Style Slide Retainers Prevent Wear

Progressive Components adds to its line of SRT slide retainers with slide lock-style slide retainers to prevent any interference with the mold during ejection and ensure proper movement of the mold.

Read MoreDeep-Hole Drilling, Milling Machine Purpose-Built for Moldmakers

Tarus highlights its lineup of DHDM machines dedicated to handling injection molds and die-cast dies.

Read MoreEDM Graphite Line for High-End EDM Machining

IMTS 2024: Mersen offers its complete family of EDM graphite, including its ultra-fine DS4 graphite. The graphite is used as the electrode which acts as a “cutting tool” in the sinker EDM, a machining process often used by moldmakers.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

Read MoreThread Mill Designed for Core Hole Creation, Chamfering

The Walter USA solid carbide TC685 orbital drill/thread mill is for hard machining of the core hole and thread in one operation.

Read More

.jpg;maxWidth=300;quality=90)