Build

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreIngersoll Introduces July 17th Die and Mold Seminar

Ingersoll is offering a mold and die seminar to place focus on proper tool selection and the application of the latest cutting tool technologies.

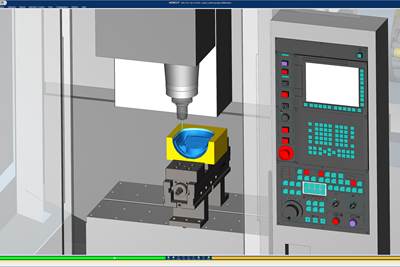

Read MoreCNC Platform Creates Adaptable Interface for Workholding

IMTS 2024: Features such as advanced collision protection and greater operational functionality make Heidenhain’s TNC7 CNC control platform critical for mold builders, who often face multi-surface machining.

WatchQuality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreButton Insert Available for Copy Milling Cutter

The Walter Tiger·tec Gold WMP45G round insert, available in several diameters and geometries, features high pocket stability to cost-effectively achieve complex forms.

Read MoreToolholding, Metrology Systems Increase Accuracy and Efficiency

IMTS 2024: Rego-Fix introduces automated tool clamping units, spindle drawbar force testing tool for increased efficiency, measurement accuracy and machining capabilities.

Read More3D Printed Manufacturing Aids Improve Molding Efficiency

Moldmakers and molders turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

Read MoreCustom Machining Solutions Feature Automation, Digitalization

IMTS 2024: Mazak features advanced machining solutions designed to boost productivity in automation, multitasking capabilities and machine tool technology.

Read MoreHMCs Improve Unattended Machining Performance

IMTS 2024: JTEKT’s FH5000 HMC with pallet pool expands the capability for more flexible production for shops of any size, such as the processing of multiple mold and dies as needed.

Read More

.jpg;maxWidth=300;quality=90)