Build

Stainless Steel Enables 3D Printing of Precision Tooling

IMTS 2024: Mantle’s 420 Stainless Steel allows manufacturers to rapidly produce production-grade tooling during prototyping and product development.

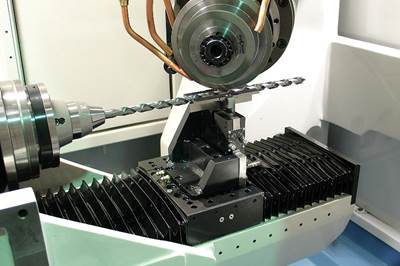

Read MoreHow to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.

Read More3D Printers, Laser Welders Target Mold Production, Repair

IMTS 2024: Trumpf introduces a larger version of the TruPrint 2000 3D printer, as well as automated arc welding, laser welding and 3D laser marking technologies, noted for their use in tool and die.

Read MoreDouble-Column Machining Centers Improve Accuracy, Speed of Mold Machining

IMTS 2024: Takumi highlights its UA400 five-axis and VC1200 three-axis machining centers for mold machining, designed to minimize thermal growth and accelerate feed rates.

Read MoreRobotic Integration Boosts Automated Milling, AM and Part Fabrication

IMTS 2024: Kuka Robotics highlights the advantage of automation in parts processing through various system partner demonstrations.

Read MoreQuick Mold Change and LSR Tooling Trends

In this short but informational MMT Chat, MMT Editorial Director, Christina Fuges, sits down with Roembke Mfg. & Design Inc.’s Business Development Manager, Adam Shaal, to talk about a quick mold change solution, LSR tooling and the future moldmaker.

WatchEDM, Precision Milling, 3D Printing Improves Accuracy, Reduces Machining Time

IMTS 2024: MC Machinery Systems showcases an array of EDM and precision milling tools, as well as a wire laser metal 3D printer, all of which have the capacity to meet moldmaking needs.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHigh-Feed Milling Insert Addition Adds to Mold Machining Optimization

IMTS 2024: New 6-millimeter inserts for the Iscar Mill-4-Feed enhances free cutting action capabilities for extreme material removal rates.

Read MoreThree-Axis Mill Delivers High Performance for Mold and Die Work

IMTS 2024: The VMX42Di machine, among other featured models, demonstrates Hurco’s Companies’ focus on productive manufacturing and automation/CNC machine tending.

Read More

.jpg;maxWidth=300;quality=90)