Compact Rotary Cooling Unit Facilitates Efficient Demolding of Rotating Cores

Available as a standard unit imold’s latest product reduces development cost, eliminates problems caused by cooling water leaks and is offered in two available sizes.

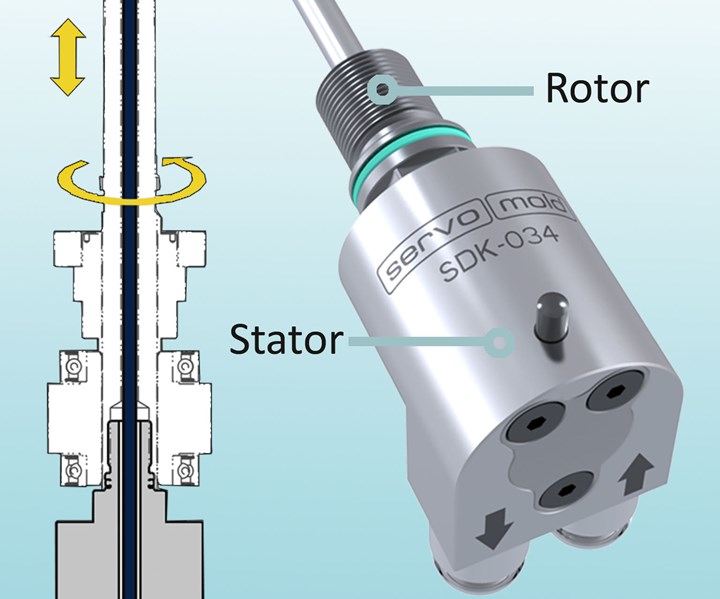

Serving the plastic injection mold industry, i-mold GmbH & Co. has developed a line of compact rotary cooling units that facilitate the cost-efficient integration of rotating cores into injection molds. The device's main components are a stator designed for twist-lock installation which also carries the coolant hose connectors, and the rotor which supports the cooling pipe as well as the thread for attaching the rotating core. Available as a standardized element, the unit is said to reduce the development cost and effort associated with the use of custom solutions. Moreover, it eliminates problems caused by cooling water leaks; each i-mold unit comes leakage-tested and is warranted as leakproof.

For multi-cavity molds, it is possible to connect up to four rotary cooling units in series. Additional groups of four can then be arranged in parallel, paving the way to design compact molds with a large number of rotating cores. As a result of this capability, plus the advanced cooling performance that supports short cycle times, i-mold’s devices help increase manufacturing productivity. Further, the rotary cooling units are suitable for all common mechanical, hydraulic or servoelectric rotating core drives.

Depending on core dimensions and cooling power needs, the unit is offered in two sizes. The SDK-034, rated at a 2-6 millimeter cooling pipe diameter, supports particularly close cavity spacings of only 34 millimeters due to its compact stator design. The 45-millimeter-wide SDK-045 is intended for higher coolant flow rates and accommodates cooling pipes measuring from 6-10 millimeters in diameter. The default cooling pipe length is 300 millimeters with customized lengths available on demand. The core attachment thread may be either metric fine or inch-type.

For connecting the coolant hoses, i-mold's units come with standard plug-in couplings. Quick-acting couplings are also available as an option. The minimum bending radius of the coolant hoses depends on the material required for the given temperature range. It is equal to 35 millimeters for coolant temperatures up to 60°C, 50 millimeters for temperatures up to 80°C and 90 millimeters for hoses rated up to 120°C. The maximum operating pressure is 10 bar (1,000 kPa). A suitable coolant is filtered water, with a filter fineness of 0.05 millimeters or below.

Related Content

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

Confronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.