Basics

How to Transition From a Cold to Hot Runner Mold

Reducing cycle time and costs while also freeing up your machines for other projects are advantages gained by using hot runners that no one can ignore. But where does one begin transitioning from cold to hot runners?

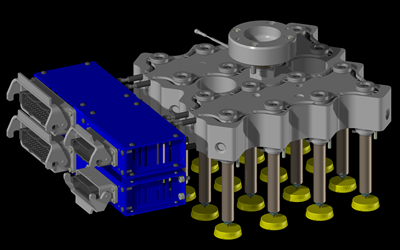

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreGet to Know Our PTXPO Exhibitors

Product, equipment or service suppliers in and around the Moldmaking Pavilion share insight into their businesses, relevant innovations and reasons for exhibiting at PTXPO.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreMMT Chats: How to Improve Efficiency in 3 Key Toolroom Areas

MoldMaking Technology Editorial Director Christina Fuges chats with James Jergens, General Manager for Triangle Tool and Penn Erie Tool of The Plastek Group about three simple ways to improve efficiency: tool design, equipment and work in process. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

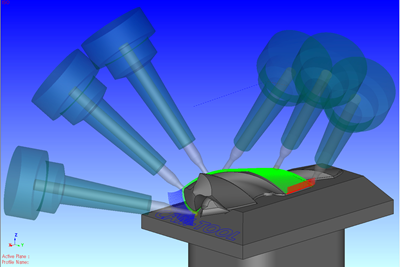

Read MoreHow to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

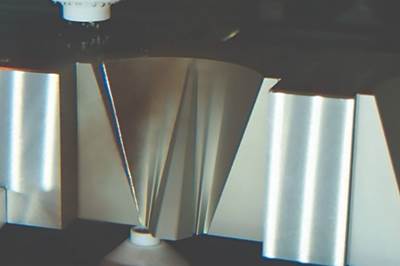

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

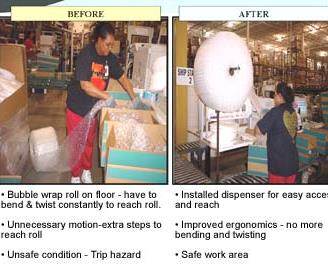

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read More