Basics

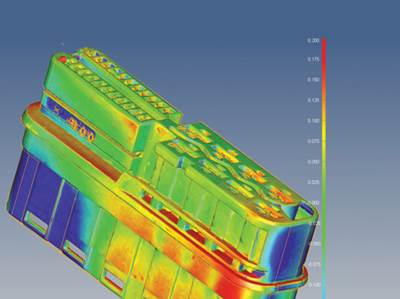

How to Save Time and Money with Faster Measurements

Today’s mold manufacturer is often looking for time and cost savings on many levels. There are solutions—whether it is to reduce development times, accelerate the configuration of entire initial sample test reports or shorten reaction times for damage analyses.

Read MoreWaukesha County Tech College: Industry Support Strengthens Curriculum

WCTC’s administration has always supported the tool and die program with the latest equipment and technology.

Read MoreHow to Maximize your Marketing Budget, Part 2

The call to action from our last article was to identify attributes about your company that attract, maintain and grow your business. Hopefully, you took my advice and asked your customers. Now you need to determine, deploy and evaluate the right marketing option to get your message out.

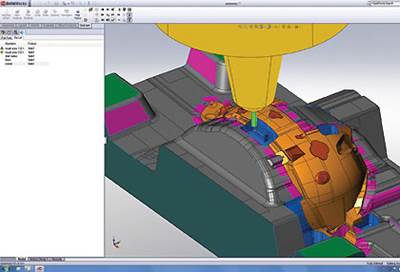

Read MoreFour Steps to CAM Selection

Considerations when choosing the right CAM system solution for your mold build operation.

Read MoreHow to Succeed with Smart EDM Operation

Factors that can contribute to the success of EDM or be detrimental to the process.

Read MoreBest Practices for Surface Finishing

In moldmaking, the surface of the mold has a direct impact on the surface of the product being molded. Because of this, proper surface finishing is essential to producing quality parts.

Read MoreIntegrated CAM for Toolmaking

A look at integrated CAM systems, and the importance of placing cost and capability at the top of the list during the selection process.

Read MoreRichmond Tooling, Inc.: Tooling, Inc.: Success with Small Mold Building Niche

A group of 11 dedicated employees—several with more than 10 years with the company—are able to keep overhead costs down and pass those savings onto its customers.

Read MoreTexturing Molds for Thermoplastics: Factors for Success

Factors to consider when selecting a texture or grain for a thermoplastic mold or die.

Read MoreSteve Rotman: Championing for Apprenticeship Training

There is no question that Steve Rotman, President of Mooresville, NC-based Ameritech Die & Mold, Inc. is passionate about the industry.

Read More