How to Succeed with Smart EDM Operation

Factors that can contribute to the success of EDM or be detrimental to the process.

Share

Read Next

The benefits of EDM have become clear to many mold manufacturers throughout the past several years. It allows for the super-precise machining of delicate, complex parts and hard-to-machine materials, and eliminates downstream operations such as polishing and deburring. Still, some moldmakers may not be getting the most from their EDMs. Several factors can contribute to the success of EDM or be detrimental to the process.

Choosing the Right Machine

First and foremost, machine selection is a huge part of operational efficiency in EDM. Depending on the application, moldmakers can choose from wire, drilling, sinker or some combination of the three.

Wire EDM: Choose a machine with the latest cost-saving features. For example, some machines have an operational mode that minimizes wire consumption by slowing down the wire feed. The right wire EDM can also help manufacturers save on energy and consumables, with features that control and optimize dielectric fluid volume and pressure, pump and filter operation, and resin consumption.

Drilling EDM: Moldmakers should look for machines that combat hole tapering—otherwise known as bullet nosing. To avoid this common problem, machines must not only use high-quality electrodes, but also feature a power supply with a low unload voltage—ideally less than 35 volts. This maintains a high speed, but reduces wear and tear on electrodes. The right type of dielectric fluid can also combat bullet nosing. Try tap water with the appropriate additives instead of de-ionized water.

CNC sinker EDM: These are ideal for cavity and rib machining, and as with wire EDM, selecting the correct machine is the key to productivity. Features such as c-axis, lateral servo, high-speed jump and state-of-the-art power-supply technology can reduce electrode wear and improve productivity. CNC sinkers with high-speed spindles can also perform the same job as an EDM drilling machine, but at a much smaller hole diameter and with more precision.

When it comes to purchasing any type of EDM, remember to consider its control technology. Many machines now have sophisticated software that incorporates 3-D modeling, which can significantly improve ease-of-use and operator efficiency.

Economical Operating Practices

Several operational strategies can help moldmakers increase the value they reap from their EDM processes. In wire EDM, for example, the type of wire used can cut costs and improve efficiency. Brass is a commonly used and cost-effective wire material, but zinc-coated wire can increase speeds by up to 15 percent for improved productivity.

Moldmakers can optimize the process of starting from holes and edges with a few simple tips:

• Use a thickness-adapting function for edge startup to avoid wire breakage.

• Locate start holes as close to the cut profile to save lead-in time.

• Starting from edges is best done on a submerged machine.

• Utilize the auto-threader of the wire EDM to run as many cut openings as possible unattended. Then the operator only has to spend time at the machine dropping slugs.

Preparing blanks is another important element of EDM that can save moldmakers time and money. Tricks such as leaving extra material for clamping; minimizing clamp and step heights when designing fixtures; and, keeping stacks as flat as possible can all optimize flushing pressure, which will improve machining efficiency.

Maintaining EDM Performance

Proper preventative maintenance is crucial in keeping EDM machines running as efficiently and economically as possible. Operators need to check and maintain consumables—such as power feeders, filters and resin—regularly to prevent unstable, inaccurate machining.

Cleanliness can also affect an EDM’s performance. Contaminants such as sludge, dirt and spray from dielectric fluid as well as burrs can compromise filter life, cause corrosion and reduce overall accuracy. Check and clean the worktable, lower arm and head, seal plate, conductivity sensor, fan cooler, filter pump and auto-threader to maintain peak performance. Also be sure to keep the machine well lubricated.

Check the power feed and ground cables regularly. Problems with them are the number-one cause of speed loss in EDM machines. The wire transport system, rollers, bearings and flush cups are other elements of the machine that are often the culprit of faulty performance.

Automation, Combination

The latest advances in automation and combined machine technologies can bring your EDM operations forward by leaps and bounds.

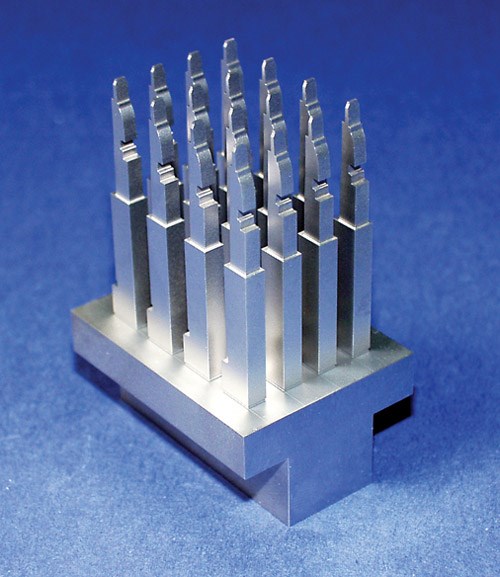

At the simple end of the automation spectrum, mechanical toolchangers can allow EDM machines to run unmanned. This process is similar to automated cutting toolchangers in CNC milling applications. In the case of EDM drilling, toolchangers store and change out the electrode tubes, while sinker EDM toolchangers store and change out electrodes. Most EDM toolchangers hold between eight and 20 tools at a time, but can go as high as 48.

Robots go one step further, holding and changing out more tools and also changing out guides on EDM drills, when needed. They can also change out workpieces on the machine table to facilitate continuous unattended or overnight machining.

Some manufacturers have employed sophisticated automated processes that combine multiple machining technologies—such as waterjet and EDM—to maximize automated run time while saving time and money. Another example is combining a milling center to mill a graphite electrode, a CNC sinker EDM to burn the mold cavity and a CMM to measure the finished part. This type of turnkey system can facilitate total lights-out manufacturing for long periods of time—freeing up operators to focus on the higher-level tasks, which can add significant value to businesses.

Summary

With the pressures to compete on a bigger and more global scale, moldmakers have been forced to do more with less. Increasing productivity while lowering costs is a goal on every mold manufacturer’s list. Fortunately, the opportunities to succeed and grow with new EDM technologies—and several tried-and-true best practices—have never been greater.

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Advances in Automation for Mold and Die - High-Performance Machining and EDM

Recent developments in automation are providing benefits for the high-performance machining (HPM) of electrodes and steel mold components.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More