Basics

Training Initiative’s "Mold VS Machine" Approach Boosts Moldmaker/Molder Relationship

“Understanding mold design helps molders understand the limitations as well as the possibilities in mold design. Molders can ask constructive and critical questions with knowledge, and also conjure recommendations and make suggestions for improving designs.”

Read MoreReady to Ignite

The AMBA's second day of conferencing kicked off by igniting the minds of the audience with a panel of 13 mold shops each sharing one critical challenge and solution.

Read MoreHow to Become a Qualified Tooling Vendor

RMM believes that moldmakers are to be proactive in “new” product design as well.

Read MoreHow to Get the Most out of Your Cooling Design

Getting the most out of a cooling design involves figuring out how to get around obstacles such as melt delivery systems (hot runners, cold runners, gates), part ejection, and mold action (slides, lifters).

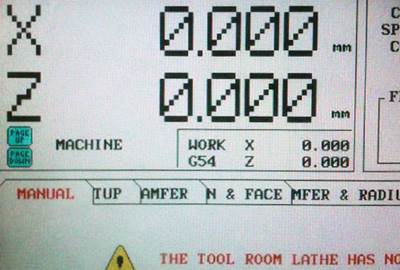

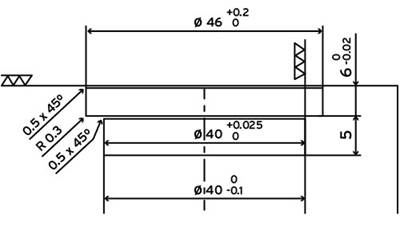

WatchThink Metric: It’s All in the Numbers, Part 2

Feedback from the field on making the metric conversion in your shop after realizing it just makes sense.

Read MorePlastics Professor Challenges Students to Design Race Car!

Plastics Professor Jon Meckley unites middle schoolers and college students to bring a plastic product design to market—from part design and verification, to tool design, tool build, and product manufacturing.

Read MoreTaking the Guesswork out of Complex Machining Processes

“Overall, VISI turns a very complicated process such as machining part geometry into a simple process that can be learned quickly.”

Read MoreTwo Strategies for Securing Skilled Labor

A number of mold manufacturers reveal their clever solutions to the workforce development dilemma—from hiring retirees to recruiting the young.

Read MoreTips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

Watch