Basics

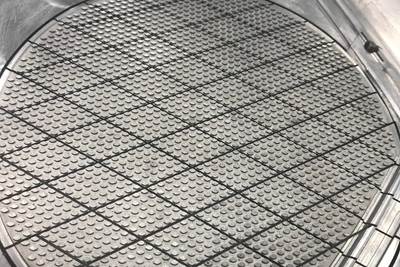

How to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read MoreTaking Care of the People Side of an Acquisition

Focusing on the human side of the business—employee health, safety, success and growth—is the only way to satisfy both the buyer and seller.

Read MoreMachining Webinar: How to Apply Accelerated Finishing Technology

Today the moldmaking industry has access to new tools and toolpath strategies that challenge traditional finish machining approaches.

Read MoreA Technical and Business Approach to Moldmaking Increases Growth Opportunities

Next-generation ownership at Kingson Mold and Machine changes culture to deliver optimized, definable and repeatable productivity solutions.

Read MoreHow to Transfer Quality Training from a Cost Center to a Profit Center

To succeed with product quality and quality training shops must measure quality at the source, process improvements, waste, cost, productivity, sales and other key performance indicators.

Read MoreComponents of a Complete Cleaning and Surface Treatment Program

Proper surface treatment of a mold optimizes the mold’s performance, limits downtime, improves performance and increases production efficiency.

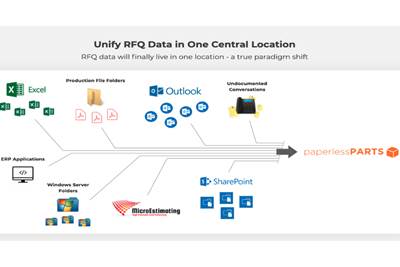

Read MoreHow to Optimize Quoting with Geometry-Guided Automation

Automated quoting improves efficiency, reduces bottlenecks, increases production speed and trims costs for mold builders.

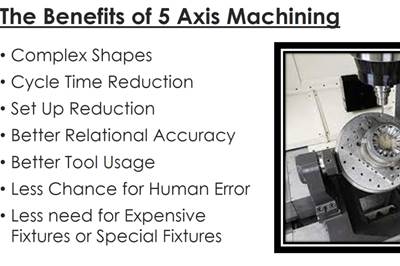

Read MoreWEBINAR: How to Take Advantage of 3+2 and Simultaneous 5-Axis Machining to Increase Productivity

“First, think about what you are doing and why,” emphasized Ken Conklin, the director of the Methods Dealer Network for Methods Machine Tools, when he shared his advice on how to implement five-axis machining in mold manufacturing.

Read MoreHow to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

Read MoreStackTeck Takes New Steps to Support U.S. Customers

StackTeck partners with Louis Young of L.J. Young Consulting LLC to expand U.S. customer support. Louis brings 35 years of injection molding project and production experience.

Read More