WEBINAR: How to Take Advantage of 3+2 and Simultaneous 5-Axis Machining to Increase Productivity

“First, think about what you are doing and why,” emphasized Ken Conklin, the director of the Methods Dealer Network for Methods Machine Tools, when he shared his advice on how to implement five-axis machining in mold manufacturing.

“First, think about what you are doing and why,” emphasized Ken Conklin, the director of the Methods Dealer Network for Methods Machine Tools, when he shared his advice on how to implement five-axis machining in mold manufacturing.

During this free on-demand webinar, Ken uses his wealth of mold and die experience to explain how best to develop five-axis machining processes within a mold shop environment. He starts off with key bullet points about five-axis machining:

- 5-axis machining is great for complex shapes (more tools to do more things)

- 5-axis machining reduces cycle times

- 5-axis machining reduces setup time (you are getting 5 sides … no flipping or flopping; you get better relational accuracy vs dimensional accuracy)

- 5-axis machining allows better tool usage (using tools not previously used)

- 5-axis machining decreases the chance of human error

- 5-axis machining reduces the need for expensive or special fixtures

He also answers questions about how the move to five-axis machining can impact a shop’s expansion into automation; the effectiveness of tabletop five-axis indexers for mold and diemakers; and the biggest challenges facing machine operators when going from three to full five-axis machining.

Other key takeaways include:

- Your part is only going to be as good as your CNC strategy and CNC tool.

- Use five-axis simulation tool paths to your advantage.

- The most common machine type is trunnion because it is more rigid; better for hard milling; solid bridge-style machine for mold and die.

- Kinematics are important; know where your kinematic center is and that its rotation is true; tilt, rotation and finding the pivot point.

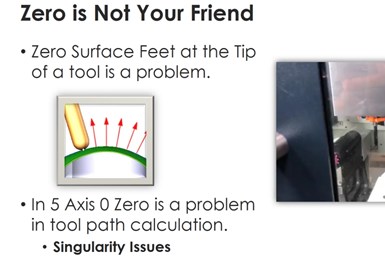

- Maintaining surface footage is critical.

- Don’t think about using a five-axis machine without the right programming.

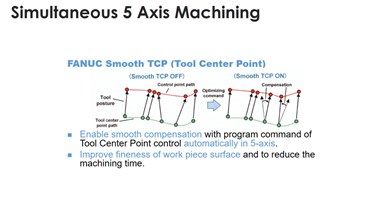

- Tool center point control allows you to program a feedrate of 200 ipm and the control will make adjustments on the fly.

- Zero is not your friend when it comes to your tools. In five-axis a 0 is a problem; it causes singularity issues. Some CAM can help; otherwise you must remove it in your programming.

- CAM can make you or break you when it comes to five-axis machining.

- CAM verifies your tool paths not your machine motion; verification software can make you when it comes to simultaneous five-axis machining.

- Adaptive milling—a good five-axis programmer can eliminate some additional semi-roughing passes because he can get into places he couldn’t before.

- The machine tool matters—make sure tilt and rotary are as accurate as possible.

- Stabilization of the machine in a shop environment is critical to maintaining accuracy.

To watch the full free archived webinar, click here.

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success