Enhancing the Benefits of Multi-Component Molding Analysis

Automatically generating surface and solid meshes of a part, part insert and mold base calls for a simulation tool for over-molding and insert molding along with a robust pre-processor.

Multi-component molding helps produce complex parts by combining several components inside the mold, eliminates the need for post-molding assembly, bonding or welding, reduces overall manufacturing costs, promotes design flexibility and improves part aesthetics, value, quality and function.

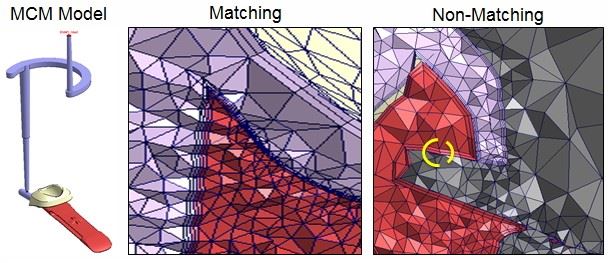

Here, Moldex3D explains how non-matching mesh technology has been extended to support the automatic creation of non-matching mesh connections between the part and the part insert/mold base, which eliminates hours of manual effort spent on matching mesh interfaces.

The first component is a part insert that is pre-placed in the cavity to be over-molded by the polymer melt. This insert can be plastic (over-molding) or metal (insert molding). The key is preparing a good mesh model that incorporates the part insert, which can be challenging when accurate analysis results need to be attained simultaneously. The solution is a simulation tool for over-molding and insert molding along with a robust pre-processor to automatically generate surface and solid meshes of the part, part insert and mold base.

Previous versions of the simulation tool from Moldex3D support non-matching mesh topology at the contact faces between the part and the part insert. Its analysis could have continuous results across the non-matching mesh boundary, which reducees the time and effort for completing the mesh preparation without bothering to match the mesh elements. This latest version extends the functionality of the non-matching feature by allowing users to generate a solid mold base for the model with a non-matching part and part insert.

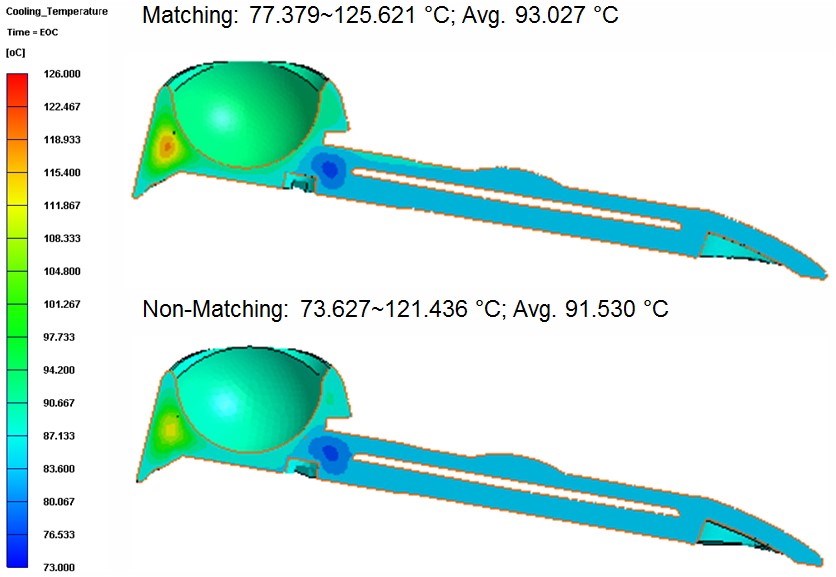

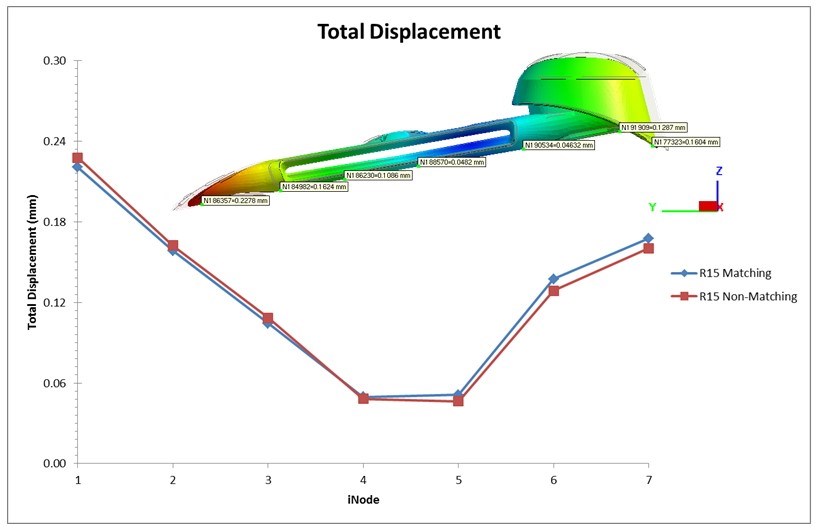

Figures 1 and 2 show an example of generating a solid mold base using the non-matching feature for an over-molding model. Both the part and part insert materials were PC+ABS, and the melt temperature, mold temperature and initial part insert temperature were 265 °C, 75 °C, and 30 °C, respectively.

The results from matching the mesh model were used as the reference for the non-matching mesh model. The temperature profile and the Z-displacement were evaluated. The simulation result of the non-matching mesh model is similar to the result from the matching mesh model, indicating that the solid mold base in a non-matching mesh model can work well.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

CT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

-

MMT Chats: 5 in 5 with Roembke Mfg & Design

Editorial Director Christina Fuges chats with Adam Shaal, Business Development Manager for Roembke Mfg & Design to reveal their five best practices for improving efficiencies in culture, technology, process, measuring success and staying competitive.