amerimold

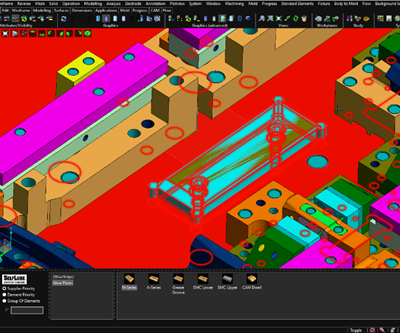

3D Models in Components Library Eliminates Busy Work for Tool Designers

SelfLube announces 3D models for its entire product line of precision mold and die components are fully incorporated into the VISI CAD components library.

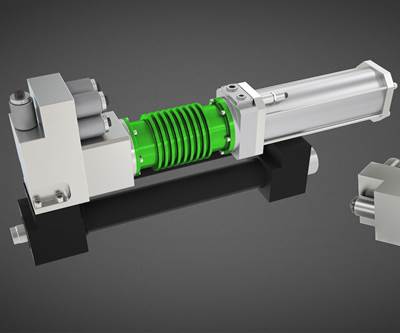

Read MoreDrive Technology Eliminates Fear of Contamination

J&H Distributor showcases the e-ahp drive, a force and position controlled linear axis capable of generating high forces.

Read MoreLaser Welder Performs Internal Mold Repairs and Engineering Changes

M&M Tool and Mold LLC has expanded its customer-based capabilities with the addition of an ID1 450-watt fiber laser welder from Alliance Specialties.

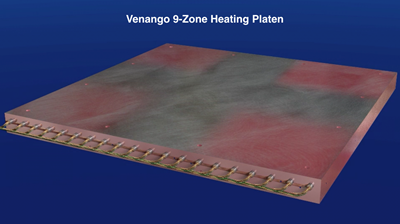

Read MoreHeating Platens Reduce Mold Surface Temperature Variation

Venango’s MultiZone heating platens with a control system reduces mold surface temperature variation by almost 400%

Read MoreRound Pallet Enables Machining with Easier Access Around Workpieces

FCS North America Inc.’s M6 round pallet is designed to address mold and die makers’ need to machine small components.

Read MoreManagement System and Clean Rooms Support Customer Programs

Innosurg Medical, the sub company of Kenmold North America LLC, provides clean room manufacturing and assembling for customers.

Read MoreGraphite Machining Capabilities Enables Tighter Tolerances

Tri-Gemini has expanded its graphite machining capabilities for high complexity electrodes.

Read MoreGantry Milling Machine Sized to Tackle Challenging Molds

Waldrich-Coburg introduces the Taurus-Gemini, a gantry variant of the company’s award-winning Taurus 25/30 vertical bridge type milling machine.

Read MoreA Unique Approach to Filling Specific Workforce Needs

Editorial Director Christina Fuges and Cavalier Tool & Mfg.’s President Brian Bendig discuss how the shop has successfully eliminated their mold design bottleneck by filling specific workforce needs.

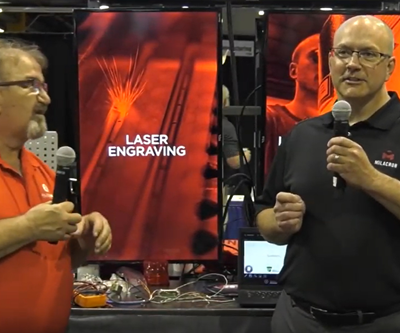

WatchHow to Correctly Diagnose Hot Runner Electrical Issues

Watch to learn how misdiagnosing temperature control issues caused by defective or incorrectly wired components can make finding root cause and solving the problem difficult and time consuming.

Watch