Additive Manufacturing

Analysis of the Additive Manufacturing (AM) Industry Worldwide, Part I

After more than two decades of research, development and use, the additive manufacturing industry continues to expand with the introduction of new technologies, methods and applications. Additive processes have had a tremendous impact on design and manufacturing, and this impact will continue to grow in the coming years.

Read MoreReduce the Time and Costs of Jig and Fixture Manufacture

When it comes to the manufacture of jigs, fixtures and assembly tools, time-to-market for new products can be reduced, overall costs can be saved and the quality of the resulting components/production can increase with the use of additive fabrication—laser sintering and fused deposition modeling.

Read MoreRapid Prototypes + Moldmaking = Profits

Is there an easy way to avoid the pains of making mistakes in the mold building world? Absolutely! There are three simple steps that you can implement into your moldmaking process that will increase the moldmaking power of your shop and reduce your stress.

Read MoreCost of Ownership: A Lifetime of Molding Savings

“There’s nothing more expensive than a cheap mold,” has been said by many a tooling engineer after a bargain of a mold began bleeding profits.

Read MoreDelving into Rapid Prototyping Technologies Attracts New Customers

Offering RP services and investing in technologies that help to constantly improve those services can help you reach potential new markets and allow your company to push the envelope of mold building technology.

Read MoreWhen to Shift: Conventional Molding or Rapid Manufacturing?

To make intelligent decisions of when to use one process over another, certain considerations must fall into place. This discussion will deal with laser sintering.

Read MoreDirect Metal Laser Sintering vs. Conventional Tool, Part Two

In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective.

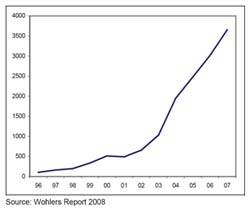

Read MoreThe Impact and Evolution of Additive Fabrication

SAn executive summary of the annual Wohlers Report that provides quantitative and qualitative analysis on the additive fabrication industry worldwide.

Read MoreNew RP Technology Reduces Costs, Leadtimes

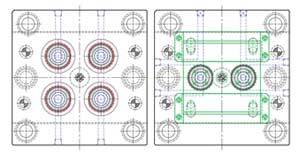

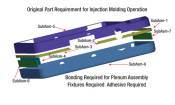

A rapid tooling process has been developed using stereolithography (SL) and a nanocomposite resin, which can result in significant savings in both leadtimes and costs.

Read MoreFusion Process from Abroad Increases Mold Performance

A select laser melting process has been developed overseas involving the fusion of a metallic powder by a scanning laser to produce complex, intricate 3-D parts that could impact the U.S. moldmaking industry

Read More

.jpg;maxWidth=300;quality=90)