Arburg Recruits 2,000th Apprentice

The company’s apprenticeship program, running for more than 70 years, has reached a major milestone with its most recent recruit, engineering technician Michael Gross.

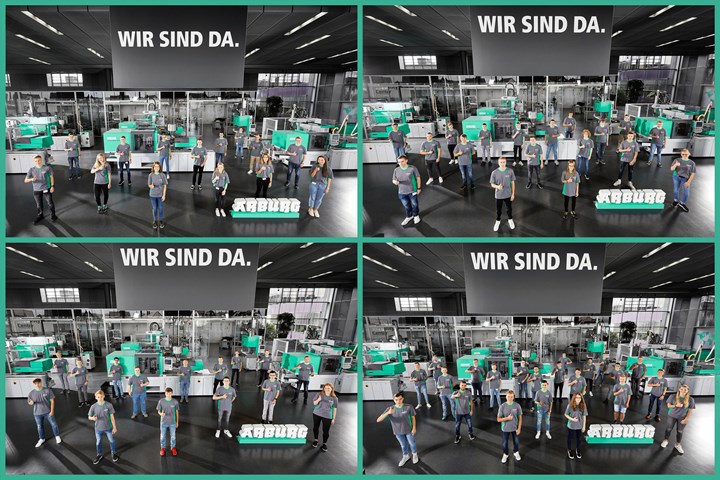

Image courtesy of Arburg

With a well-founded apprenticeship program that has been awarded three certifications, machine manufacturer Arburg (Lossburg, Germany) is now celebrating a major milestone—recruitment of its 2,000th apprentice, engineering technician Michael Gross. Gross began his apprenticeship at the company on September 1, 2020, alongside 69 other apprentices and students from Baden-Wuerttemberg Cooperative State University (DHBW).

“As the 2,000th apprentice to start their career with us, we have reached a new milestone in our apprenticeship program, which has now been running for more than 70 years. This is something that we are especially proud of,” says managing partner Renate Keinath. In order to ensure a smooth transition from theory-based school teaching to the real world of work, Arburg provided an induction week with a varied program, including the opportunity to get to know each other and become familiar with the company and its products with organized safety instructions, a detailed tour of the plant, team-building events and a barbeque.

Keinath also acknowledges that the program has continued unabated, despite a global pandemic. “We are continuing our apprenticeships unabated and enabling the 70 new apprentices and DHBW students we have taken on in 2020 to embark on a successful start to their working lives,” says Keinath. She adds that the availability of apprenticeships isn’t something that can be taken for granted in the times of coronavirus and the associated difficult economic situation, as many other companies have discovered. The fact that Arburg takes on almost all of its apprentices and students each year as permanent employees is the result of careful strategic planning. While other companies have withdrawn apprenticeships, Arburg is planning to offer even more in 2021.

Renate Keinath goes on to explain that well-trained employees with broad expertise are essential to ensuring the competitiveness of a global company and emphasizes the high-quality apprenticeships on offer at Arburg: “You will be the ones who deploy your know-how to drive our company forwards in future! We are committed to providing you with superb professional training. The 261 apprentices and students currently working for us clearly underline the high value we place on apprenticeships.” This commitment, says Arburg, is also demonstrated by the fact that Arburg is said to have become the first Baden-Wuerttemberg-based company offering apprenticeships to hold three quality certifications, after receiving its most recent accolade at the start of 2018. The company’s 2,000-sqaure-meter Education Center, and the 14-strong team of instructors led by head of Apprenticeships Michael Vieth, provide the ideal conditions for learning.

To continues it and its apprentice’s success, Arburg is already looking for enthusiastic and committed young people to join its next apprenticeship program, which will begin in September 2021. Those interested becoming an apprentice or enrolling with Arburg as a DHBW student will find all the relevant information here.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

.jpg;maxWidth=300;quality=90)