3D X-ray Microscope Extension Enables Dimensional Accuracy

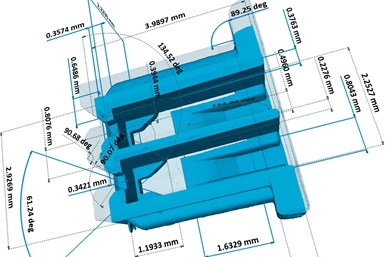

The Metrology Extension (MTX) from Zeiss offers high-precision measurements of small components and complex parts.

Zeiss has released the Metrology Extension (MTX) for Zeiss Xradia 620/520 Versa. The extension enables dimensional measurements that are more accurate than conventional X-ray computed tomography (CT) technology, according to Zeiss. Zeiss recommends the MTX for assessing internal and external structures, particularly components that are not accessible to traditional tactile or optical CMMs, such as internal cavities, difficult-to-reach or ‘hidden’ features and flexible or easily deformable materials. It can be calibrated to a Maximum Permissible Error (MPE) value of (1.9 + L/100) μm.

“The miniaturization and integration of components in smaller devices is creating an increasing demand for high-resolution metrology in industrial manufacturing,” according to Herminso Gomez, X-ray quality solutions manager at Zeiss Industrial Metrology.

The MTX is designed to determine dimensional deviations from the nominal geometries defined in computer-aided design (CAD) for functional features in small components, such as injection-molded plastic connectors or fuel injector nozzles. Complex parts, such as a smartphone camera lens assembly, can be measured using a variety of criteria. “With the Metrology Extension, our users receive traceable results in the smallest of volumes,” Gomez says.

The MTX option adds the ability to make measurements in small volumes (in a cube of 5 mm per side, for instance) with high dimensional accuracy. Zeiss also offers XRM Check, a length measurement standard, in accordance with the relevant VDI/VDE 2630-1.3 guidelines. Thanks to the integrated, user-guided calibration workflow, users can calibrate their Zeiss Xradia Versa X-ray microscopes to a verified measurement accuracy of MPESD = (1.9 + L/100) μm, where L is the measured dimension in millimeters. This allows the collected data to be accessible for further dimensional analyses with standard metrology software. MTX is available as a field upgrade option and for new instruments.

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.