Welding Repair Services for Additive Manufactured Molds

Precision Laser Technology relies on its experience and expertise in laser welding and tool metallurgy to ensure mold repair success, including a recent partnership with Mantle to to prove out AM technology.

Precision Laser Technology (PLT), a service shop specializing in laser applications that includes texturing, engraving, welding and direct part marking, has been supporting the mold building industry for nearly 20 years. Located in Upstate New York, PLT prides itself on delivering high-quality, reliable laser services within the moldmaking community and keeping pace with technology advancements within the industry.

To assist customers with mold maintenance and repairs that ensure durability and quick response, PLT operates four laser welding stations, plus a micro-TIG station, ranging up to 300W and optimized with multiple axes systems, boom extensions and CNC programming as well as tilting and swiveling optics. PLT welds molds built from a variety of tool metals, including, most recently, 3D additive metals.

Mantle Inc. an additive manufacturing (AM) technology manufacturer, recently introduced a hybrid CNC/3D printing platform that is able to print, shape and sinter injection mold cavities and cores using a metal paste with similar steel properties as traditional tooling. As AM technology becomes more favorably integrated into the mold design and build, PLT notes that continued laser weld support is inevitable for wear, engineering changes and unexpected damage.

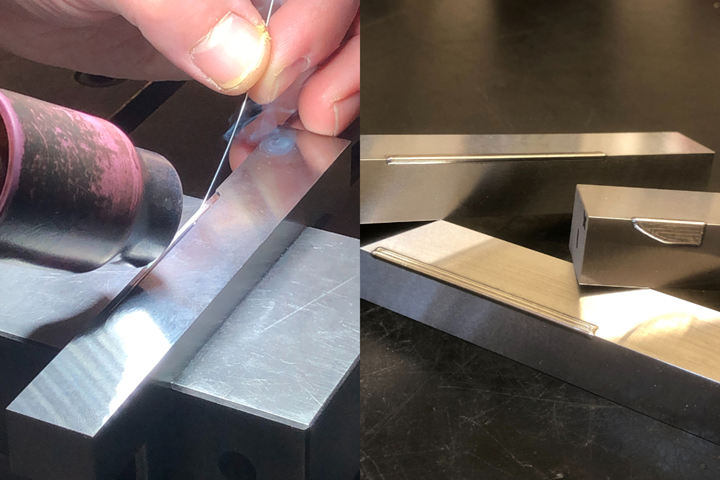

Recently, PLT and Mantle conducted a study to repair 3D-printed bars built from Mantle’s H-13 metal paste utilizing laser applications and conventional machining methods. The printed bars rated a Rockwell C hardness of 42 and were precision ground to within 0.0005" to assess surface quality and machining performance. There was zero evidence of pitting and no signs of wheel loading or heat generation during grinding. The finished bars were then damaged along the edge to simulate a worn out parting line or mold crash from a misaligned insert. The scope of repair included CNC milling, laser welding and post grinding to the datum surface. According to the partners, the printed bars accepted the filler rod readily and showed no visible sign of heat sink. PLT performed additional experiments that included engraving, texturing and polishing and concluded that the H-13 metal paste behaved similar to traditional H-13 tool steel.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.