Threaded Inserts for Metal Ensure Secure Fit When Repairing, Replacing Worn-Out Threads

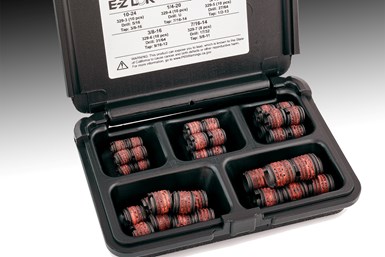

E-Z Lock (Solid Wall) threaded inserts by E-Z Lock come in assortment and installation kits, enabling moldmakers to efficiently repair and reinforce threaded holes.

E-Z Lok, a manufacturer and distributor of threaded inserts for metal, plastic and wood, now offers E-Z Lok (Solid Wall) threaded inserts for metal, including both assortment and installation kits.

E-Z Lok inserts are ideal for repairing or reinforcing threaded holes in soft metals such as aluminum, magnesium and cast iron. They are also useful in moldmaking, for affixing plates, heater elements, etc. when completing the mold. External threads are standard size and pitch, so they can be installed with standard drills and taps. Solid wall threaded inserts are installed with a screwdriver, bolt/jam nut (except IC series) or optional power drive tool.

These inserts will not back out or vibrate loose. The pre-applied, microencapsulated adhesive begins to set immediately upon installation and the installed insert is fastener-ready in 3-5 minutes. Despite their firm hold while in use, E-Z Lok (Solid Wall) threaded inserts for metal can be removed with a bolt extractor, which overcomes the resistance to torque-out produced by the adhesive. They can also be removed by heating the insert to a temperature above 300°F, at which point the adhesive will release.

E-Z Lok inserts are available in thin wall, standard wall, extra heavy wall, screw locking and automotive designs. They are available in carbon steel and stainless steel. Stainless steel threaded inserts are well suited for applications requiring additional corrosion resistance, as well as food, beverage and other clean-critical applications.

Assortment kits are equipped with inserts in a variety of sizes. They provide an easy-to-store solution for thread repair, giving maintenance teams added convenience. Installation kits are specifically designed to make threaded insert applications and repairs as simple as possible. These feature a drill, tap and installation tool.

CAD files on this product can be downloaded in more than 100 file formats from the E-Z Lok website at https://www.ezlok.com/cad-downloads.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

.png;maxWidth=300;quality=90)