Strategic Workforce Management Supports the Moldmaking Industry

NPE2024: Kruse presents its workforce management framework for optimized organization and management of human resources.

Source: Kruse Analysis Inc.

Injection molding simulation service and technology provider Kruse Analysis Inc. is celebrating its 30th anniversary at NPE 2024. Kruse’s focus on designing top-notch and economically viable molded components coincides with the company’s Kruse Training division dedicated to education in the injection molding sector since 2018 using an ATR (attract, train and retain) framework for optimized workforce management. The company’s other division, Molding Expert, targets virtual reality training solutions.

At the core of Kruse Training is “The Circle of Knowledge” learning principle, which forms the bedrock of its comprehensive curriculum tailored to industry needs. Currently, the platform offers 111 active lessons, with a new course on Plastic Drying set to launch within the year. The introduction of the “Micro Lesson” project, featuring 5-8-minute lessons, facilitates rapid knowledge acquisition, offering quick refreshers and introductions to new topics.

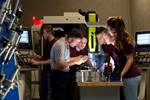

With the help of Molding Expert, Kruse Training implements eLearning complete with virtual reality training methods for recruiting and developing a skilled engineering workforce. In today’s modern world, the prevalence of technology makes clear that quick learning is key to asserting a competitive edge in mold design and moldmaking.

The company says eLearning techniques in the moldmaking industry are the first steps toward a more sustainable economy. The progression includes technological advancements, cost-effectiveness and resource optimization, accessibility and inclusivity and the impact on employee productivity and retention. These factors encapsulate the reason why this advanced and strategic workforce management in the moldmaking industry is successful.

The forthcoming virtual reality molding facility is an immersive application that enhances the effectiveness of the training programs by enabling users to virtually navigate a molding facility with audio-enhanced explanations of various equipment and tools. Furthermore, the mold design review (MDR) tool offers a comprehensive examination of injection molds, with audio descriptions and interactive elements for in-depth exploration of mold designs.

Related Content

-

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

-

MMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.