Five New Design of Experiments Lessons Available

Kruse Analysis provides part designers, mold designers and senior process engineers with five new sessions on the subject of design of experiments (DOE).

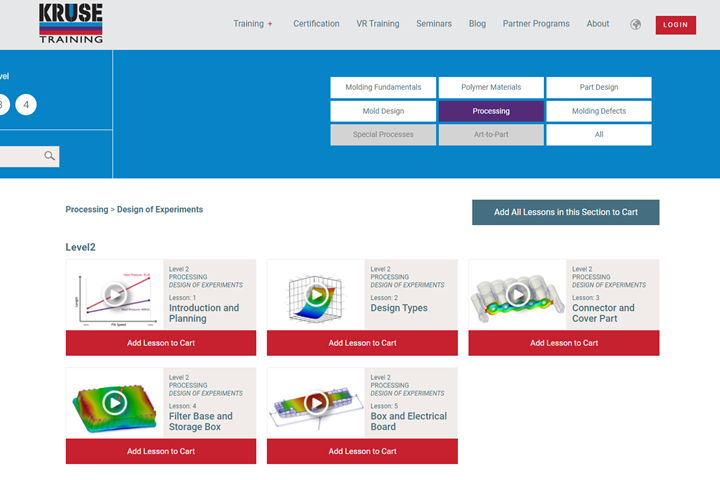

Photo Credit: Kruse Training

Kruse Training, an online knowledge and training solution for part designers, mold designers and senior process engineers, has made five new design of experiments (DOE) lessons available. This includes Introduction and Planning; Design Types; Connector and Cover Part; Filter Base and Storage Box; and Box and Electrical Board.

DOE is a mathematical tool that can be successfully applied to areas of new mold trials and troubleshoot potentially challenging processes. Experimental design techniques can be used by anyone with a fundamental understanding of injection molding. This section covers the fundamentals of DOE and how to apply a DOE strategy for molding quality parts.

Kruse Training’s new lessons break down the basics of running a DOE and then take students through specific examples of how to apply the theory to real-world examples. All sessions are clear, concise and walk students step-by-step for a complete understanding of concepts.

Goal of the DOE lessons are:

- Learn the theory and framework of establishing a DOE strategy and how to apply this knowledge to real-world molding examples.

- Learn the five stages of conducting a DOE strategy and how to utilize various charts and graphs to analyze the data.

- Learn about several design types and how they can be applied to DOE.

Kruse Training lessons can either be purchased individually or by sets on a specific subject.

Related Content

-

Confronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

MMT Chats: It’s Time to Play … The Moldmaker Card Game! Yes, a Game to Educate and Entertain

MoldMaking Technology Editorial Director Christina Fuges connects with Professor Steffen Ritter from Reutlingen University in Germany about the card game for moldmakers he developed to help promote and educate our next generation of moldmaking professionals in a fun way. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.jpg;maxWidth=300;quality=90)