Software Package for Portal Roughness Gages Streamlines Surface Data Interfacing

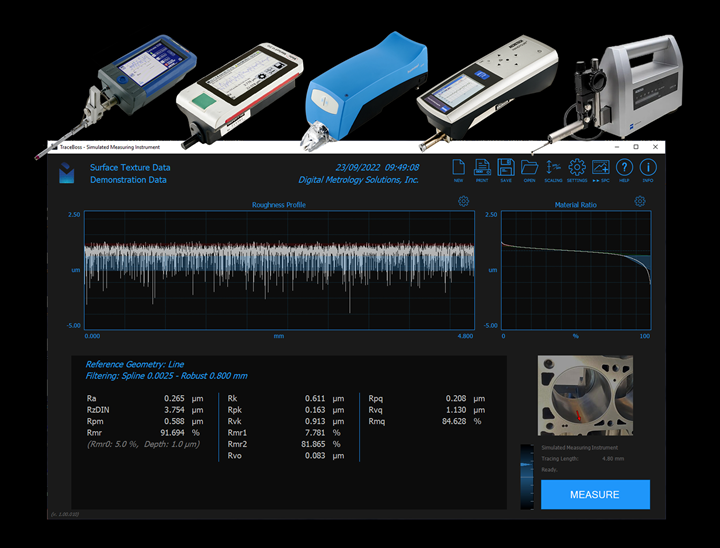

Digital Metrology Solutions offers mold builders a fast, affordable way to better understanding of surface data with the TraceBoss software package.

Digital Metrology Solutions, provider of measurement software, consulting and training, has introduced the TraceBoss software package for portable roughness gages, equipment that is imperative to high-precision workpiece measurements and is considered to be indispensable for injection moldmaking.

“Most portable gages show you a roughness number or two and perhaps a small image of a profile on a tiny screen,” Mark Malburg, president of Digital Metrology Solutions, explains. “As a result, many users are eager to do more with their data. TraceBoss gives portable gage users the power of a high-end instrument at a far lower price, and in an easy-to-use package.”

The TraceBoss software interfaces with most portable surface roughness gages via a USB connection. One click in TraceBoss configures the gage, initiates a measurement and presents the results and graphics full screen and in high resolution. The software display is optimized for the highest visibility in shop environments.

With most portable gages, the profile and data cannot be easily saved or recalled, Digital Metrology Solutions explains. TraceBoss reportedly makes it possible for a gage user to save data and easily reload it for comparisons, traceability and statistical process control.

TraceBoss calculates and reports most common roughness parameters. Optional tolerance highlighting shows at a glance whether a surface passes or fails relative to user-provided limits. A side-by-side display clearly shows the relationship between Rk and Rq family parameters and the peaks and valleys that they describe.

A wide range of portable surface gages from Zeiss/Accretech, Mahr, Taylor Hobson, and Jenoptik/Hommel Etamic connect to TraceBoss with minimal setup. The help system includes quick setup guides for each supported gage and step-by-step instructions for all software functions.

More information, purchasing options and a free 10-day trial download are available at digitalmetrology.com/solution/traceboss.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.