Software Demonstrations Feature Simulation Tools for Analysts

Autodesk has three demonstrations available at NPE2018 to higlight Moldflow Insight and Moldflow Helius, Moldflow for Design and Powermill.

Autodesk features three demonstration stations at NPE2018. One focuses on Moldflow Insight and Moldflow Helius, another on Moldflow for Design and the third on manufacturing.

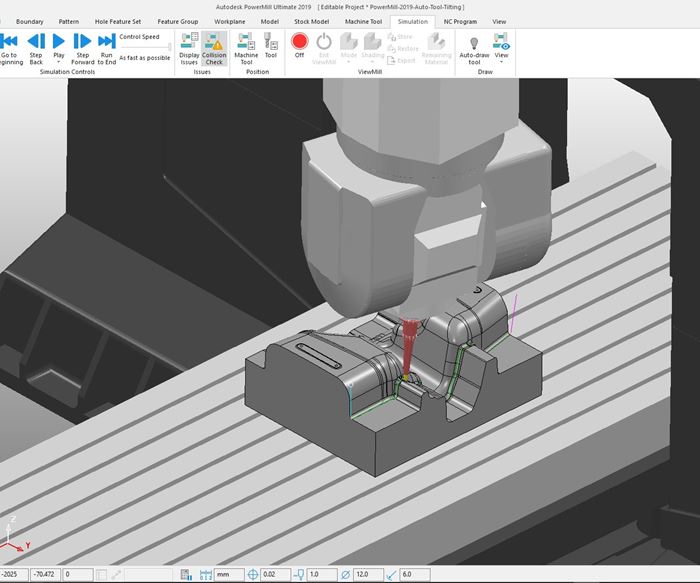

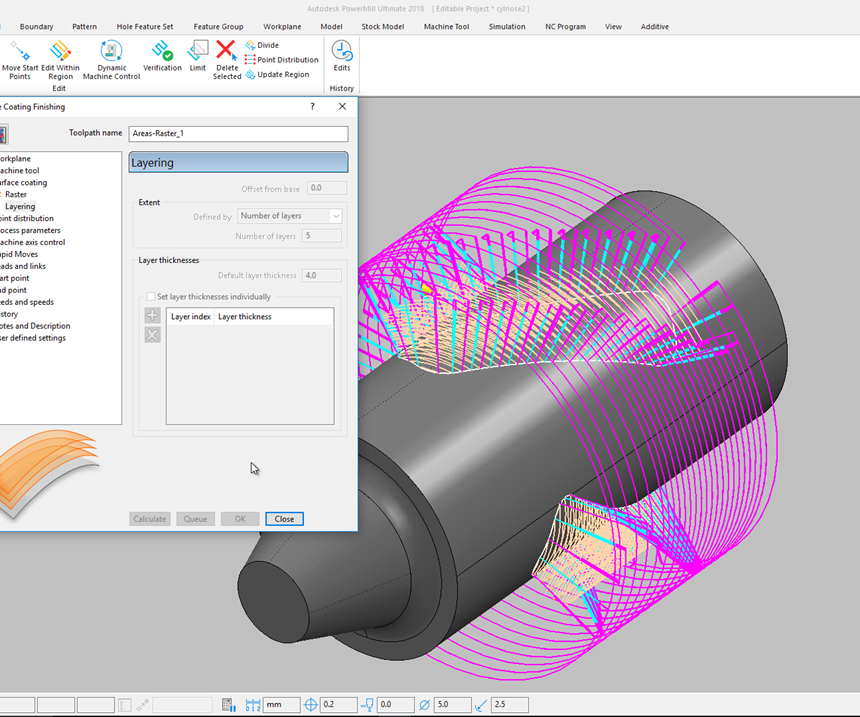

Moldflow Insight is a complete set of plastics engineering simulation tools for analysts. Helius Composite software offers detailed information on composite material behavior without finite element analysis. Moldflow Adviser is a plastic simulation tool that optimizes part and mold designs to ensure molded part quality and manufacturability. PowerMill CAM software provides milling strategies for high-speed and five-axis machining.

PowerMill offers a comprehensive range of tools to enable the manufacturing of molds, tools and other complex shapes and is capable of driving both wire-fed and powder-blown hardware with three- and five-axis machine motion. PowerMill also provides an improved workflow for the definition of open-sided 2D features. PowerMill also includes an interface to Autodesk Fusion Production, which is a cloud-based collaboration tool specializing in scheduling and tracking production.

Related Content

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.