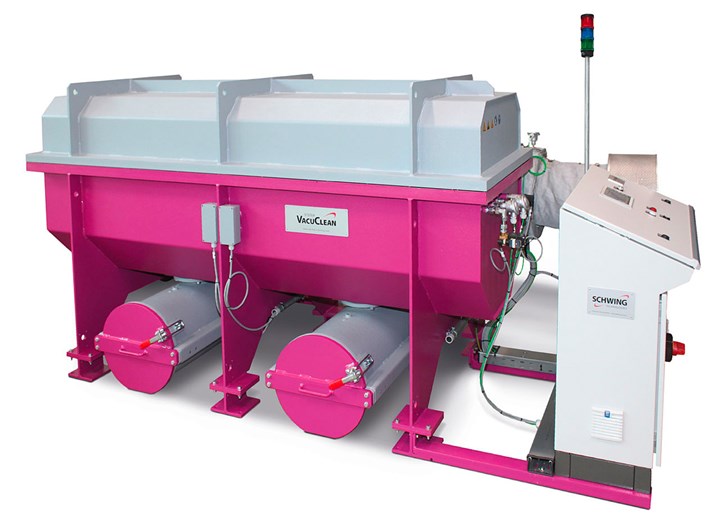

Schwing Showcases VacuClean Pyrolysis System

Amerimold 2021 exhibitor Schwing Technologies presents VacuClean, a vacuum pyrolysis system that reportedly removes plastic residues from tools, dies and filters without thermally impacting them.

Photo Credit: Schwing Technologies.

Schwing Technologies highlights its VacuClean pyrolysis system at Amerimold. VacuClean is a vacuum pyrolysis system for removing plastic residues from critical machine tooling, dies and filters. According to the company, VacuClean removes polymer from tooling within eight to 30 hours, depending on the system size, components to be cleaned and polymer type. It is designed to clean parts without impacting them thermally or mechanically. It features an integrated catalytic converter system to clean exhaust air and wastewater.

VacuClean’s automatic cleaning process takes place in an electrically heated vacuum cleaning chamber. Schwing states that the temperature of the component is measured directly on the surface of the component to be cleaned, which is initially heated slowly. As the part heats, most adherent polymer melts and drains off. The remaining polymer disintegrates once the system reaches around 850°F. Remaining carbon is removed by adding air (oxidation). A sensor system controls the cleaning process, reportedly preventing the development of excess temperatures. Inorganic residues can be removed through post-treatment, such as with compressed air.

Exhibitor: Schwing Technologies

Booth E-410 (P)

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.